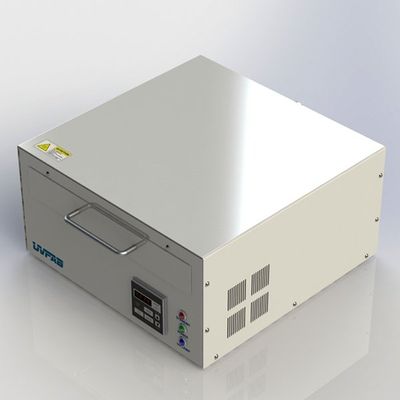

The table-top and compact UV Ozone Cleaner, HELIOS-1200 is designed to remove molecular levels of organic contamination to achieve atomically clean surfaces on various types of substrates. A high intensity UV grid lamp (12″x12″) generates 254nm ultraviolet radiation which breaks the bonds of organic molecules on the surface as well as strong emission at 185nm that converts atmospheric oxygen into reactive ozone, which attacks the small molecular fragments and creates volatile organics.

This compact tabletop UV Ozone Cleaning system features a large drawer-loaded sample stage with a UV exposure area of 12” (W) x 12“ (D) and boosts UV and ozone production using a custom synthetic quartz UV Grid lamp. This system can process one 300mm (12″) wafer, one 200mm (8″) wafer or four 100mm (4″) wafers. Operation is as simple as placing your samples in the process chamber, closing the drawer, and setting the desired process time on the digital timer. This system features a drawer safety interlock to protect users from UV and ozone exposure during the cleaning process. There is also an hour counter to keep track of the UV lamp life time as well as a 2-inch O.D. exhaust port if needed.

The HELIOS-1200 system features a high-intensity 12″x12″ UV Grid lamp for greater ozone production, excellent uniform UV exposure and faster cleaning rates. The small-footprint system is easy to operate, and use a unique combination of ultraviolet radiation and ozone to gently, yet effectively, remove organic materials from a variety of substrates including silicon, gallium arsenide, sapphire, metals, ceramics, quartz and glass. The HELIOS-1200 UV/Ozone Cleaner is well suited for a variety of applications such as substrate cleaning, photoresist descumming, wettability improvement, surface modification, surface activation and UV curing. By operating at atmospheric pressure, the HELIOS-1200 system eliminates the need for a cumbersome, high-maintenance, vacuum system and will not damage delicate electronic devices.