- Home

- Companies

- Buckau-Wolf GmbH

- Products

- Buckau-Wolf - Vacuum Pans with ...

Buckau-Wolf - Vacuum Pans with Honeycomb Calandrias

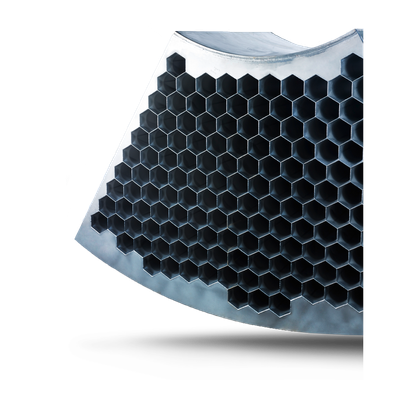

Buckau-Wolf Vacuum Pans equipped with honeycomb calandrias are engineered to enhance industrial crystallisation processes by reducing boiling time and energy consumption. These patented calandrias feature a unique design where pipes are arranged in a honeycomb pattern, optimizing the heating surface and facilitating efficient heat transfer. The system includes a central circulation pipe and a stirrer that ensures thorough mixing and directed flow, resulting in improved crystal structure and reduced processing time. Designed in compliance with the European Pressure Vessel Directive, these devices are versatile, supporting retrofitting to upgrade existing systems with minimal modification. They integrate easily into operation, making them a preferred choice in sugar factories worldwide, offering efficient heat exchange and homogeneous material suspension. Additionally, Buckau-Wolf provides comprehensive engineering and inspection-related services, including CAD drawings, welding instructions, and documentation in multiple languages, ensuring adherence to technical standards and operational safety.

Buckau-Wolf Vacuum Pans with honeycomb calandrias increase capacity by shortening the crystallisation time while simultaneously reducing power consumption.

Our portfolio includes the engineering, specification, calculation, and production of boiling devices in accordance with the European Pressure Vessel Directive (PVD) 2014/68/EC and the German regulations for the specification and manufacture of pressure vessels AD 2000-HP0.

We create inspection-capable CAD drawings, welding instructions, welding specifications, inspection plans and the relevant documentation in the desired language. This includes inspection reports, manufacturing drawings, manuals, risk assessments, declarations of conformity, material certificates, transfers of identification, pressure tests, process inspections and all other required acceptance documents.

We also conduct non-destructive testing on pressure vessels.

Buckau-Wolf Vacuum Pans are equipped with patented honeycomb calandrias. These calandrias consist of pipes that are welded in a honeycomb pattern without a pipe bottom (pipe plate). This minimises the distance between plates and optimises the heating surface ratio.

A central circulation pipe and the stirrer ensure optimal mixing and a directed flow in the device and ensure a homogeneous suspension as well as intensive exchange of heat and micro-volume mixing.

The result is a better crystalline structure at a significantly reduced boiling time.

Summary

- Recognised throughout the world for their high level of efficiency and top-quality sugar crystal

- Retrofit to existing systems at any time

- 25 % more heating surface for the same installation space in comparison to conventional pipe heating chambers

- 75% reduction of depositing surfaces on the top side of the chamber

- The optimized chamber design ensures homogeneous crystal growth and improved CV values (variation coefficient) in the massecuite

- Minimum redirection losses, dead zones, and local overheating

- Best flow conditions guarantee a homogeneous strike, and the stirrer uses less power

- Energy savings when vapour-cleaning the device

- Expanded capacity by reducing the boiling time at identical steam quality or lower energy costs through lower steam quality at consistent boiling times; the resulting excess energy can e. g. be used to generate electricity.

Buckau-Wolf honeycomb calandrias for retrofitting can be installed into existing systems with little effort.

This applies in particular to the exchange of pipe calandrias, lenticular calandrias, and ring calandrias. During retrofitting, the pipe length and the heating surface are determined again and adapted to the demand of the sugar factory.

Benefits of retrofitted vacuum pans

- Ready-to-install delivery of segmented Buckau-Wolf honeycomb calendria with or without stirrer

- Retrofit to existing systems with ring, lenticular or pipe calandrias without modification of regulators, pipelines, devices or buildings

- Boost the output of existing systems by up to 25% by enlarging the size of the heating surface

- Low maintenance costs and a long service life