UFG - Model VPMF -Variable Pore Backwashable Micro Filter

Though there are numerous technologies available for separating contaminants from polluted water, one of the simplest and most ef-fective is the filtration method. Filtration has been defined as one of the best separation technologies as it is not dependent upon chemi-cal treatment and it prevents re-contamination.

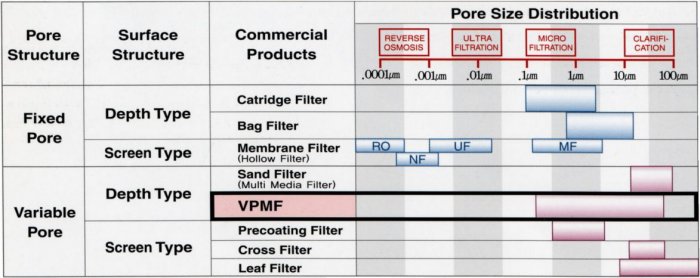

Most of the previously utilized filtration technologies have been conventional sand and media filtration, cartridge or bag filtration, ceramic, highly polymerized compounds and membrane filtration. These products, which are manufactured from various raw materi-als and are readily available in the market, have the respective pore sizes which range from tens of microns to ionic particle size.

Although these technologies are capable of filtering as intended, they are only marginally utilized in the municipal and industrial marketplace. Such utilization has been limited to small purification plants and other simple treatment processes. The hindrance to com-plete utilization of these filters has been primarily due to very lim-ited cleansing capabilities of the systems.

Previous micro-filtration systems have had either limited or no back-washing capabilities which was due to the design parameters of the systems. Conventional fixed pore micro filtration systems have also been restrictive in use due to the high cost of element replacements. Cleaning of the elements has been difficult due to penetration of the matter into the pore structure of the element.

The introduction of the VPMF (Variable Pore Micro Filter) system revolutionizes the entire concept of micro filtration. As shown in figure 1, filtration products are usually classified by pore structure and surface type. Most of the previous conventional, variable-pore structure filters have been limited to removal of particle size larger than 15-microns. Visualizing the need for a superior micro-filtration system, Global Enfiltec Inc. developed the VPMF system, which has been developed, tested and proven with over ten years of performance. VPMF systems are being operated and maintained at over 200 facilities throughout Korea, Australia, Japan and Western Europe.

Introduction of the VPMF System

Operation of the VPMF system is entirely different from the traditional media or cartridge filtration systems. The VPMF has been defined by users as the perfectly back-washable micro filter. It has been patented in the USA (Patent No. 5984108), Japan (Patent No. 3131190) and Korea (Patent No. 0241198). Further patents are being applied for in various countries.

Principles of Operation

Filtration Cycle:

In the filtration mode, the micro fiber element is compressed by the raw water in a down-flow filtration pattern. The inflow of raw water gradually compresses the micro fibre element until optimum compression is reached. Suspended solids and sediment are trapped in the folds of the micro fiber element.

Backwash Cycle:

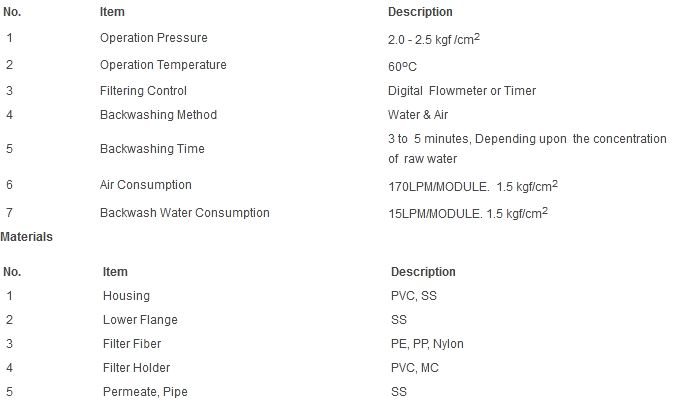

In the opposite manner, back-washing is completed by expanding and dividing the pore structure into strands, which are easily cleaned with finely diffused air and water. Vibration of the cylindrical element in the air wash cycle results in a synergism which enhances release of matter from the fibres. Backwash takes only 3 – 5 minutes depending on the raw water makeup.

- The filtration process operates with multiple layers of micro fiber

- The backwash process is very rapid, requiring only 3 - 5 minutes.

- Perfect backwashing is achievable by means of water and air.

- There are five models available ranging from 25-micron to 0.2-micron

The VPMF system may be utilized over a wide range of applications such as potable water purification, sewage and wastewater treatment, pre-treatment of advanced water treatment processes and the removal of green algae such as chlorophyceae.Uses for the VPMF system:

-

Purification Plants

The VPMF is capable of replacing conventional sand filters, cartridge filters and MF membrane systems. - Polluted Water Treatment

The VPMF is able to remove the SS, and to decrease the BOD after biological treatment. - Sewage Water Treatment

After biological treatment, the effluent from the VPMF systems can be utilized for irrigation purposes. - Waste Water Treatment

The levels of COD, BOD and SS are dramatically reduced by use of the VPMF . - Pre-treatment for Advanced Water Treatment

The VPMF may be utilized as pre-treatment for membrane systems, ion-exchange, ozone, activated carbon, and UV systems. - Removal of algae and other organisms

The VPMF has been found to provide excellent performance in removal of chlorophyceae in aquatic fish ponds, process water recirculation, cooling tower filtration, vehicle washing recirculation and numerous other raw water conditions.

VPMF has been developed to meet the needs of the next generation of technology for filtration and separation in liquid phase.

- Reduced maintenance compared to conventional media filtering systems

- Reduced water consumed in the BW process

-

Less floor space is required, which results in lower capital cost

- Excellent backwashing relates to cost savings of energy

- Extended life expectancy due to the superior backwashing performance

- Modular design allows for easy expansion in capacity

- Economical in terms of initial investment

- Tremendous removal capacity of suspended solids

For sewage applications, the effluent from VPMF systems can be used for irrigation purposes in golf courses and parks after biological treatment. For industrial waste water applications, the effluent can be recycled and reused for production purposes, thereby avoiding the waste of this valuable commodity.

- Makes recycling usage feasible for irrigation and industrial process water.

- Removal of chlorophyceae possible by removing SS, BOD, T-N and T-P simultaneously.

- Protects drinking water sources against pollution.

- Restore environmental friendly parks with artificial rivers for the public.

- Recycling of industrial wastewater.

- Easily accommodated in existing facilities.

- Less space required and lower maintenance costs.

- Eliminates waste water effluent due to recycling

- Enhances the client reputation as being environmentally friendly.

- Maintain less than 10 PPM of both BOD and SS.

- Enables improvement of water quality without interrupting the operation of an existing facility.

- Fully automated operation by means of a PLC control system.

- Less space required and lower maintenance costs.

- Can replace existing sand and micro filter units.

- Extends life expectancy of RO systems and Ion exchange resins.

- Perfect backwashing performance ensures high efficiency.

- Modular design allows for easy future expansion.

- Prolongs useful life of machinery due to removal of suspended solids.

- Lower production cost owing to the most optimum recycling system.

- Less backwash water produced due to efficiency of BW process.

- Fully automated operation by means of a PLC control system.