ENVEA - Model SpeedFlow 2.0 -Velocity Measurement Sensor for Solids

Continous speed measurement for solids usable in free fall and pneumatics. Especially designed for continuous measurement of velocity of solids and particles such as granulates, powders and dusts, which are transported in free fall or in pneumatic transport. Uses triboelectric correlation technology.

- Continuous speed measurement of solids (powder, granules, dust ) in metal pipes

- Measurement directly in the conveying stream / entrained flow

- Measurement is completely independent of material

- Simple retrofitting using a welding socket

- Energy

- Material to measure: Dust, powders or granulates

- Working principle: Correlation

- Process pressure: Max. 1 bar

- Process temperature: Max. +80°C, optional +120°C

- Mounting: Via process connection

- Type of Conveying: Pneumatic leanphase

- Velocity range: 0,75…35 m/s

- Pipe diameter: No limit

- ATEX rating: None

- Output: 4…20mA, Modbus, Profibus

- Materials: Granules, Powder and dust

- In metal pipes

- Can be used in free fall lines or in pneumatic conveyors

- Range of application: starts with material speed as low as 0.75 m/s

Sensor Technical Data

- Weld-on socket: St52 or steel 1.4571

- Rod: Wolframcarbid

- Housingn: Steel 1.4571

- Protection category: IP 65 to EN 60529/10.91

- Rod length: 15 mm

- Velocity range: 0.75…35 m/s/td>

- Temperature inside the pipe: -20…+80 °C

- (higher temperature on request)

- Temperatur outside the pipe: 0…+60 °C

- Power supply: 24 V DC

- Weight: Approx. 1.5 kg

- Dimensions: Ø 60, Ø 20, L 320 mm (incl. rod length)

- Measuring accuracy: ± 1 %

- (in the calibrated measuring range)

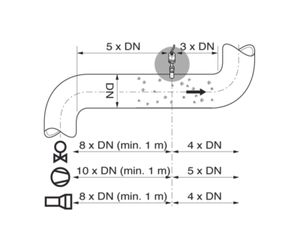

For the assembly of the sensor, the installation location is specified in accordance with the conveyed inlet and outlet paths. The socket is welded on at the specified installation location and then a borehole of 20 mm is drilled through the socket and through the line. The sensor is then adjusted to the wall thickness, inserted and fixed with the help of the coupling nut. The distance between sensor and analysis unit can be a maximum of 300 m.