Veolia Anita Mox - Wastewater Treatment System

Anita™ Mox, Veolia Water Technologies anammox process, is a cost-effective and sustainable solution for the treatment of streams highly loaded in ammonia, such as municipal effluents from anaerobic sludge digestion, drying condensates, industrial wastewaters and landfill leachates. Compared to conventional nitrification-denitrification processes, the Anita Mox process achieves an ammonia removal efficiency of over 90% with no use of external carbon source and at a very low energy cost, thus making it the ideal solution to reduce operating cost and improve the environmental record of a wastewater treatment plant.

Anita™ Mox is a cost-effective and sustainable deammonification solution for the treatment of streams highly loaded in ammonia.

Overview

High ammonia concentration with low chemical oxygen demand (COD) concentration are typical characteristics of the rejected water coming from dewatering of the digested sludge. Usually sent back to the main wastewater flow, the treatment of this ammonia load through conventional nitrification/denitrification can be quite cost-intensive or in some cases jeopardize downstream sludge digestion processes intended for sludge reduction or enhanced biogas production.

To address these issues, Veolia Water Technologies subsidiary AnoxKaldnes has developed Anita™ Mox, an alternative solution to conventional nitrification/denitrification processes that limits the impact of digestion on the main wastewater treatment plant line. Anita Mox is another application of the well proven Moving Bed Biofilm Reactor (MBBR) technology. Using a single-stage MBBR with a proven aeration control strategy, Anita Mox not only dramatically (>85-90%) reduces ammonia, but also removes nitrogen by 75 to 85% on the main treatment line, making it an ideal solution to upgrade an overloaded existing wastewater treatment plant, at a competitive cost.

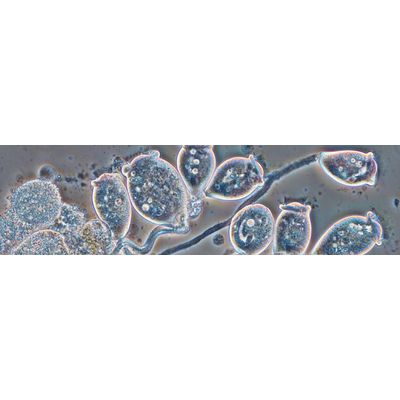

An anammox process takes place in two steps: aerobic nitritation by ammonia oxidizing bacteria and anoxic ammonia oxidation performed by anammox bacteria. In Anita Mox, the two steps take place simultaneously in a single reactor.

The aerobic and anoxic reactions both occur in a single MBBR reactor equipped with plastic carriers specially designed to support the biofilm. In the reactor, specific conditions are maintained in terms of pH, temperature and oxygen level for the ammonia-removing bacteria to provide the optimal environment to develop as a biofilm on the carriers, thereby preventing washout of the bacteria from the reactor.

A key element of the Anita Mox process is the incorporated cloud based holistic service that allows for real-time optimization of process performance.

Based on operational data from online sensors and algorithms, this digital solution calculates optimized setpoints for equipment, to adjust parameters, providing a state-of-the-art auto-pilot to optimize the whole treatment process.

Hubgrade and its Services allow clients benefits from start-up all the way through continuous operation allowing them to optimize environmental, operational and financial performances.

Compact, robust and flexible process

Best in-class security against anammox bacteria loss

No carbon source needed

Reduce sludge production

Almost 60% oxygen savings

Reduce electric power consumption by 60%

Lower CO2 emission

Municipal wastewater treatment

Optimized management of effluents and wastewater.

Industrial wastewater treatment

Technologies, services and process expertise to meet environmental requirements, remove contaminants and transform wastewater into a resource.

Sludge valorization: making better use of your resources

Application

Sludge treatment

Sludge valorization: making better use of your resources