- Home

- Companies

- Rawlings Manufacturing, Inc.

- Products

- Rawlings Wood Hog - Model VRM Super XI ...

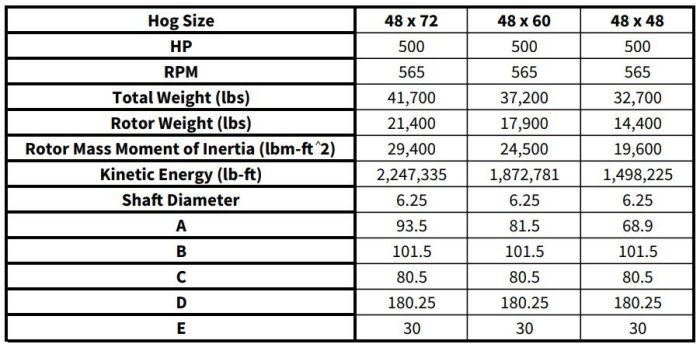

Rawlings Wood Hog - Model VRM Super XI -Vertical Feed Rear Maintenance

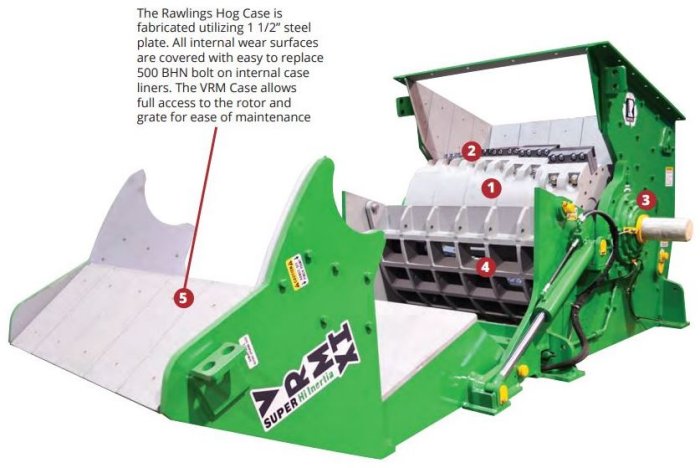

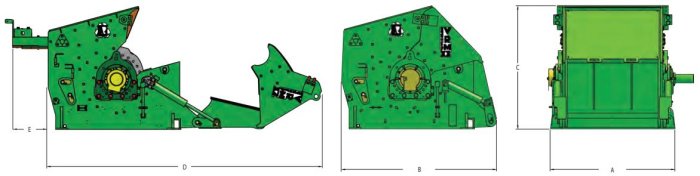

Introducing the “VRM” Super XI Vertical Rear Maintenance Wood Hog from Rawlings Manufacturing Inc. No cookie cutter machine can meet everyone’s space constraints or challenges. We have had several customers over the years that wanted a Rawlings solid rotary hog but did not have the overhead clearance in their existing footprint to allow for a clam shell opening type of machine. The VRM hog opens hydraulically from the rear of the machine allowing full access to the hog’s internal wear components and rotor for ease of maintenance. All Rawlings Hogs are equipped with our Patented Super Hi-Inertia Rotor that powers through feed surges with ease while still running at lower RPMs than all other machines on the market. This saves our customers both maintenance and electricity costs.

- Introducing the “VRM” Super XI Vertical Rear Maintenance Wood Hog from Rawlings Manufacturing Inc. No cookie cutter machine can meet everyone’s space constraints or challenges. We have had several customers over the years that wanted a Rawlings solid rotary hog but did not have the overhead clearance in their existing footprint to allow for a clam shell opening type of machine. The VRM hog opens hydraulically from the rear of the machine allowing full access to the hog’s internal wear components and rotor for ease of maintenance.The Rawlings Super Hi-Inertia Hog provides the crushing and shearing power needed to handle really tough jobs like green waste, cypress, redwood, cedar, black spruce, poplar and a wide range of other stringy and fibrous material

- Super Hi-Inertia Rotor supplies massive kinetic energy to power through the largest feed surges

- With increased inertia of the Rawlings Super Hi-Inertia Solid Steel Rotor our machine runs at lower RPM’S resulting in overall savings of electricity and maintenance costs

- Tolerant of Contaminants, Rocks and Metal without catastrophic maintenance costs if metal enters the grinding chamber

- Alternative Fuels

- Biomass and Co-Generation

- Sawmills & Forestry

- Pulp, Paper & Pellet Plants

- Compost Operations

- Recycling Facilities

- Waste to Energy Plants

Developed from rock crusher technology, the tough Rawlings Wood Hog uses both shear and impact to reduce material.

- Can handle really tough to grind materials like stringy cedar, black spruce, lily pads and log ends

- Tolerant of rocks and metal without catastrophic damage to machine

- The highest crushing impact rotor in the industry supplying massive kinetic energy to power through the largest feeding surges

The Rawlings Hog is a simple but sophisticated design that incorporates low maintenance technology throughout:

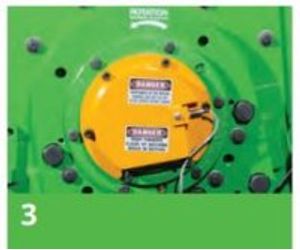

- Upper case is opened hydraulically for quick and easy service access

- Simple design reduces parts inventory and is easy to maintain

- Tremendously strong structure and oversized components

- Easy replacement of all wear surfaces and components

- One third lower RPM than other types of hogs reduces both nechanical wear and fines generation

Our machines are designed to operate 24/7 365 days a year. Bottom-line productivity, pure and simple.

The Rawlings Patented Super Hi-Inertia rotor runs at lower RPM’s than our competitor’s machines and half the speed of conventional hammer mills resulting in overall savings of electricity and maintenance costs

Rocwear striker plates are easily rotatable and replaceable when worn and provide tremendous wear life with superior grinding performance. The Rocwear system consists of a striker base which gets bolted onto the rotor. When one side is worn, the bit is rotated doubling the life of each bit

The bearing housing assembly is designed to be maintenance friendly allowing for simple removal and installation of hog bearings

Heavy duty reinforced grate assembly with rotatable grate assembly. The bolt in design makes changing out the grate much simpler and allows the grate liner to be rotated to maximize liner life. Optional grate patterns are available for different applications and end product requirements