- Home

- Companies

- Idroelettrica S.p.a.

- Products

- Verticalfire - Fire-Fighting Units with ...

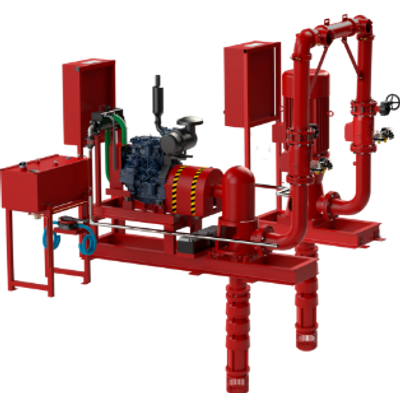

Verticalfire - Fire-Fighting Units with Vertical Turbine Pumps (VTP)

The fire-fighting units designed by Idroelettrica adhere to the UNI EN 12845 standards and are equipped with Vertical Turbine Pumps (VTP). These units are engineered to provide reliable and robust fire protection across various applications including shopping centers, hospitals, infrastructure projects, industries, hotels, residential buildings, cinemas, theaters, and schools. Each component of these units meets strict industry requirements, ensuring high performance and safety. The units feature a range of accessories such as GSM modules and external sirens to enhance operational efficiency. They offer significant advantages including durability, compliance with safety standards, and ease of integration into existing systems. The manufacturing specifications underline the use of high-quality materials and advanced engineering practices to meet rigorous safety standards.

- Shopping Centers

- Hospitals

- Infrastructure

- Industries

- Hotels

- Residential

- Cinema and Theaters

- Schools

Each component of the unit meets the requirements of UNI EN 12845, in particular there will be:

- Main pumps with submerged axial flow vertical axis (VTP), with connection heads for electric motors and/or transmission angle for the connection of a diesel motor UNI EN 12845 10.1

- Electric and diesel motors with power exceeding that required by the pump at the peak of the power curve (for diesel motors the delivery curve is that NA) UNI EN 1284510.1 – 10.9.1 – 10.9.3

- Pump/diesel motor coupling universal joints

- Electrical control panels equipped with an EPRO control unit fully connectable to the Ethernet network Delivery columns with diameters sized according to UNI EN 12845 13.2.3 complete with non-return valves that can be inspected

- Submerged type pilot pump complete with control circuit