Regulator Cetrisa - Model R-INOX -Very Low Iron High Intensity Metal Separator

The Very Low Iron Metal Separator (R-INOX) has a drum of high remanence with highly powerful magnets that can separate iron metal from light iron metal (similar to stainless steel) and from the inert.

Within the metals, iron metals should be considered as the highest percentage elements and are the most easily captured by magnetic fields.

However, the light iron metals, similar to stainless steel, are sometimes highly difficult to separate, whether it`s because of their little magnetic remanence or even for being joined, in proportion, to large non-iron fragments that make their process and separation more difficult.

Aware of this problem, Regulator-Cetrisa has developed a complete line of Equipments for Separating and Recycling LIGHT Iron or VERY LOW Iron Metals (R-INOX), similar to stainless steel, for separating, recycling and recovering them.

The functioning physical principle of the High Intensity Separator (R-INOX) is the creation, in the output drum at the end of the conveyor belt, of an intense magnetic field that acts on the iron metals and also on the light iron metals, such as stainless steel.

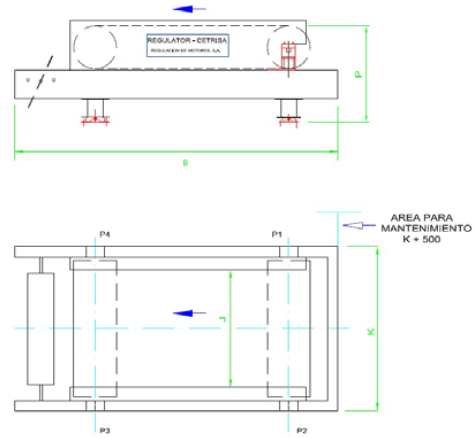

The HIGH INTENSITY SEPARATOR of VERY LOW IRON METALS (R-INOX) is made up of a robust metallic structure. This structure is the support for two drums and the conveyor belt. The conveyor belt moves over an antimagnetic stainless steel table that guarantees a perfect horizontality. It also has an automatic maintenance system for the centre of the belt to guarantee its correct operation.

The output drum is a magnetic roller made up of Neodymium-Ferrous-Boron (NdFeB) magnets, in studied configurations, which are the magnets that provide the most energy on the market. This intense magnetic potential is also capable of separating small iron material that other equipment, such as an overband, has not been able to attract and separate.

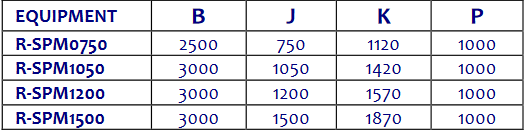

REGULATOR-CETRISA offers equipment with effective working widths of up to 2,500 mm. and with different drums adapted to the flows and characteristics of the materials that should be processed. For this reason that there is working equipment in many different sectors, such as: RAEE, VFU, wood, plastic, etc.

Besides the separation of materials similar to stainless steels, other regular applications of the Separator of Very Low Iron Metals (R-INOX) are, for example:

- For the treatment of wood, after the pre-crushing, the R-INOX equipment can separate fragments of wood that have any small remains of embedded iron (nails, studs…).

- When profiles of aluminium are processed, they often have embedded nails and studs of contaminating iron metal. With the R-INOX equipment, these profiles are separated from the material flow.

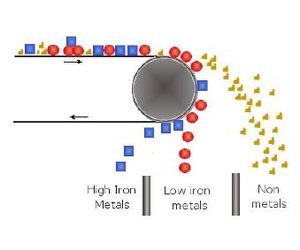

When the material flow reaches the output roller, it is subjected to the intense magnetic field generated in the drum, in such a way that the following results are obtained:

Low iron metals (stainless steels): Influenced by the intense magnetic field. Their path falls with retention and therefore they are between the “Non-metals” and “High Iron metals”.

High iron metals: Attracted by the intense magnetic field and are collected in the space between the two equipment rollers and towards the end of the equipment.

Non-metals: Not influenced magnetically and fall from the belt following their natural ballistic path.

REGULATOR-CETRISA offers equipment with different configurations and effective working widths up to 2.000 mm, adapted to the materials that should be processed. For this reason there are equipments working in many different sectors, such as: Urban Waste Plants, WEEE, ELV, wood, glass, plastic, etc.

REGULATOR-CETRISA uses all of its experience to determine the ideal equipment for every application. Besides its own experience from innumerable applications, the technical department evaluates all the necessary parameters, such as: flow, density, humidity, aggregate grading, etc.

REGULATOR-CETRISA offers the possibility of testing materials in its own facilities, where the client can verify the effective separation of the metals. This way, we can ensure satisfactory results.

REGULATOR-CETRISA, thanks to its continued investment in R&D&I, offers the best technology for integrating equipment and systems into its processes and Complete Turnkey Installations.