- Home

- Companies

- Alpha Acoustiki S.A

- Products

- VIBRO - Model TiLe - VERSATILE RUBBER ...

VIBRO - Model TiLe -VERSATILE RUBBER TILE FOR GENERAL VIBRATION ISOLATION

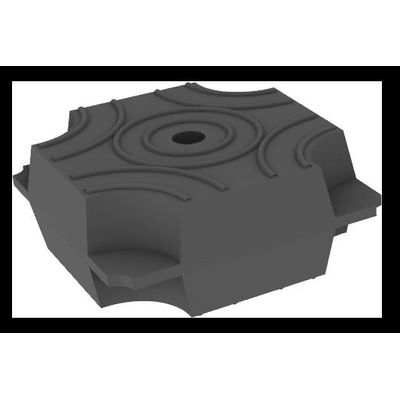

Vibro-TiLe are versatile vibration isolation pads made of special compound rubber. They reduce noise, high frequency vibration and impact from machines. They are shaped in a versatile modular waffle design. They are molded in a sheet that consists of 4X4 vibration isolation pad basic modules with dimensions of 50X50mm and they can be cut in pieces according to the specific needs of each application. A thin membrane separates the pads to provide evenly dimensioned sections that can be placed side-by-side to accommodate a machine’s load. They are made of high tensile strength rubber compound and high shape factor, with a thickness of 20 mm, which contributes to increasing the nominal deflection and the effectiveness of vibration isolation. They reduce machine impact, noise, as well as high frequency vibration.Techical characteristics

Supplied as a mat of 16 modular tile pads joined all together (4x4).

- Modular design for flexibility of load choices

- Individual 50 x 50 mm pieces can be easily cut to form the required support pattern

- Converts to a flexible support base when used with passing through screws

- Reusable in the event of machine relocation

- Easy to install

- Wide load capacity range

Several layers of pads can be stacked on top of one another for additional deflection,

when steel separation shim stock is used between them.

Application

Vibro-Tile pads are suitable for use under compressors, HVAC units, pumps, fans, AHU,

heat pumps, generators, transformers, presses etc.

In most applications Vibro-Tile can be self-supporting and stay stable, due to increased

friction (circular rings on the bearing bases).

For applications where restraint is required, there are specially designed preformed conical

holes for an M8mm screw for fixing to the machine and/or floor. Ιf an M6 screw is used, it is

also recommended to use a suitable washer.

These holes are designed to not alter published load vs. deflection performance, due to not

need for on-site perforation.