- Home

- Companies

- Shanghai VOR Separation Technology ...

- Products

- VOR - Model DSP - Dewatering Screw ...

VOR - Model DSP -Dewatering Screw Press

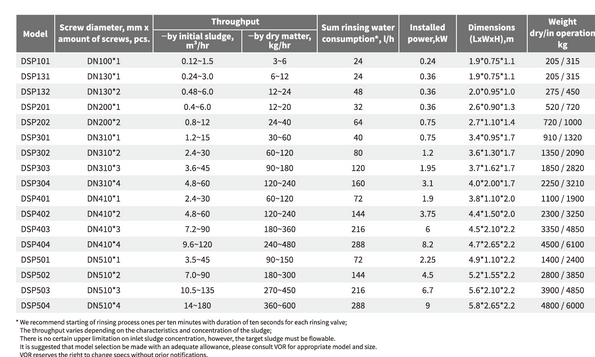

The unique design of the structure allows self-cleaning during the dehydration process, which effectively prevent clogging and save flushing water cost. The main unit of the De\vatering Screw Press (DSP) is a very simple, slow moving mechanical devise that ring-shaped "fixed discs" and "movable discs" are alternately arranged at a certain gap around a "screw shaft". DSP series can be used in an extremely wide variety of solid-liquid separation, or de\vatering applications. It has made possible the direct de\vatering of low concentration oxidation ditch or waste activated sludge. The already proven superior performance is enhanced by auto self-cleaning function that enables stable and constant dewatering without continuous flushing and allows 24 hr unattended operation 7 days per week.

How Dewatering Screw Press Works

The raw sludge is fed in to the inlet Chamber by a sludge feed pump; a predetermined amount of sludge naturally flows into the Flocculation Chamber, the excess volumereturning to the sludge tank via the overflow pipe- Polymer and sludge are thoroughlymixed in Flocculation Chamber, from there, the flocculated sludge flows bygravity into the DSP tube for processing. The effluent and solids aresimultaneously separated and discharged, and the End Plate will further improvethe sludge cake dryness.

For high density solids such as DAF sludge where flocculation has been previously performed, the thickened sludge can flow directly into the DSP for dewatering. There is no certain upper limitation on inlet sludge concentration, however, the target sludge must be flowable.

We recommend starting of rinsing process ones per ten minutes with duration of 15-30 seconds for each rinsing valve.OMRON

Electrical equipment: Schneider

Wide application

Can be widely used in municipal sewage, food processing slurry, slaughtering and breeding wastes, printing and dyeing sludge, paper mill, tanneries, pharmaceutical, and other industrial slurries.

This equipment is an optimum choice for treating sludge that contains high oil content,such as DAF froth which filter cloth systems and centrifugal decanter cannot readily handle. What*s more, the equipment boast s a higher solid capture rate.

Clog- free and Continuous operation

The filtration surface consists of a multiplicity of discs, additionally due to left and right rotation of the moving discs, foreign substances in the gap can be permanently removed, therefore it seldom clogs and the equipment can run continuously.

Capable of treating low concentration sludge

The dehydrator has both a gravity prede\vatering unit and compression dehydration main unit, and therefore can cope with a wide sludge concentration range of 0.5 to 5%.

Fully automatic operation

Due to the unique design, the operators can begin auto operations of the DSP and related accessories by simply and easily operating the included control panel. It allows 24 hr unattended operation per day.

Inhibition of secondary pollution

The DSP main unit features a semi-enclosed construction, and runs at an extremely low speed, therefore sludge does not splatter from the equipment. The DSP is of eco-friendly design and generated low noise and vibrations, and emits virtually no odors.

Low OPEX due to the small amount of flush water and low maintenance

Because of the equipment is constructed to avoid dogging, flushing is not needed in order to restore the original filtration performance. Only showering with a minor amount of water is necessary to wash away sludge mat oozes from the dehydration section-Thus, the amount of flush water needed is minimal.

Compact design

The dewatering screw press is of compact unitized construction with all of the necessary accessories and control panel mounted on a common base, and therefore can be readily installed in very limited floor space.