- Home

- Companies

- Walair B.V.

- Products

- Walair - Easy Drum Separator

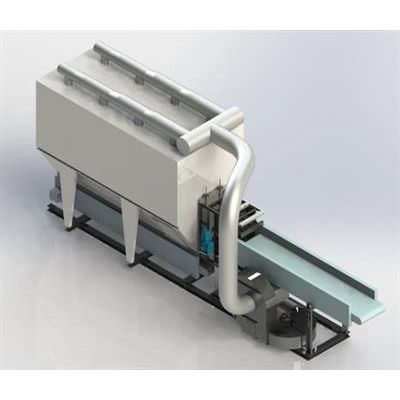

Walair - Easy Drum Separator

The Easy Drum separator is made in a width of 600 till 1200 mm. The separator can separate a waste stream in two waste streams, one consists of heavy parts and one stream of light waste. The Easy Drum separator is almost ready to use when it is delivered.

The Walair Easy Drum separator is suitable for building and demolition waste, compost, broken glass, debris, garbage, etc.

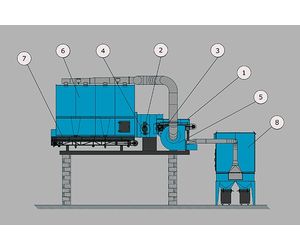

- speedupband

- roterende drum

- blaasmond

- afvoerband zware fractie

- ventilator scheider

- expansiekamer

- afvoerband expansiekamer

- stoffilter

After the material which must be separated, is transported by a conveyor, the material must equally be distributed and spread on the speed up conveyor (nr 1) of the Easy Drumseparator unit. To guarantee an optimal result of the separation, it is advised that the thickness of the material on the conveyor is no more than 30 mm. It is advised to handle parts no longer than 500 mm. in the drum separation unit. Longer is not a problem, but the long parts can run over the drum into the light fraction.

The speedup conveyor is adjustable in a horizontal and vertical position and in an angle. Below the conveyor a blow mouth is installed. Also, the blow mouth (nr 3) is adjustable in a horizontal and vertical position and in an angle. To adjust the air flow, the blow mouth is made with 2 air regulation valves.

Behind the speedup conveyor a separating room is mounted. In the separating room, a rotating drum of 600 mm (nr 2) is fitted. The drum can turn left or right. The inlet opening and the opening between the separator are height adjustable.

In the separation room, using the blowing capacity of the blow mouth and the suction capacity above the separating drum, the heavy and the lighter fraction will be separated.

Both the inlet, as the distance to the drum till the discharge chute to the expansion room, can be adjusted in height. Along the front of the drum, the heavy fraction is, by means of a chute, discharged to a discharge conveyor (nr 6) or will directly fall down in a container or bunker. The discharge conveyor is not part of our delivery.

The lighter fraction is blown over the separation drum and extracted and discharged to the expansion room (nr 6). In this expansion room, the air is separated from the material. Below the expansion room, a discharge conveyor (nr 7) is installed.

To create a suction flow above both the separation drums, the expansion room is finished with internal boxes which are, by means of 2 suction ducts, connected to one fan separator (nr 5). The fan will provide the suction for 100% of the air of the sedimentation room.

In the fans, the air is separated in an air dust flow of approx. 20% and a blow air flow of approx. 80%, and is used to blow the fraction against and over the separation drum.

The air dust flow (20%), containing the dust, is discharged to a dust filter (nr 8). The fan separator is finished with two regulation valves. These valves determine the amount of air to the blow mouth, and the amount of air which must be discharged to the dust filter.

The special fan separator allows the installation of a relative small dust filter, due to the circulation of most of the air. Using these possibilities and the possibilities to adjust the speed-up conveyor of the drum separator horizontal and vertical and in an angle, it is possible to adjust the unit to the necessary input flows and fraction sizes.