- Home

- Companies

- Guangzhou Shincci Energy Equipment Co., ...

- Products

- Shincci - Model SHS Series - Waste Heat ...

Shincci - Model SHS Series -Waste Heat Sludge Dryer

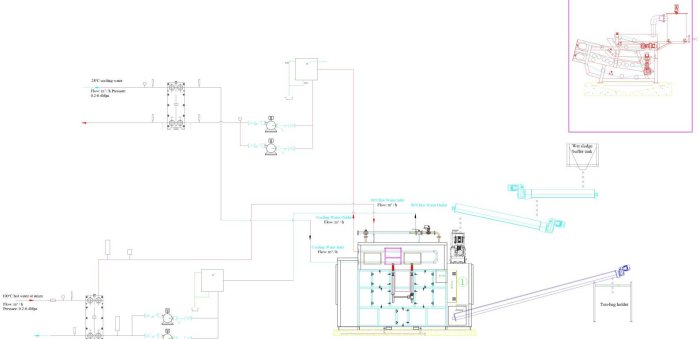

One integrate module: Heat pump + mesh belt + insulation board, easier on-site installation. Upgraded corrosion resistance: condenser, evaporator and refrigerant pipelines, heat pump support are SUS316L. Hot water/Gas/Generator waste heat can be utilized. Two modules share one belt-driven type blower, which makes cleaning and maintenance easier. Flexibility and efficiency on overhaul work:upgraded quick-opening type service access door.

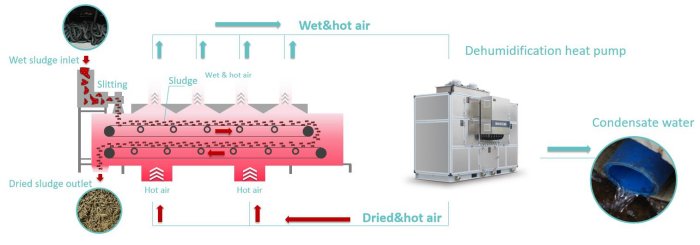

The waste heat dryer`s heater and cooler used to condense and dehumidify the sludge by hot air circulation.

Dehumidification recycle the latent heat of water vapor and sensible heat of air, without any waste heat discharge in the process.

90% of traditional sludge thermal drying system converts heat into exhaust heat loss (latent heat and hot air sensible heat)

Waste heat dryer utilized low-graded excessive thermal source, such as flue gas waste heat; Steam or Steam condensate water; Anaerobic digestion (obtain fuel gas to heat water); Sludge pyrolysis (obtain fuel gas to heat water); and Gen-set waste heat, so as to transferred into 90C hot water for drying. Because of using waste-heat, the drying process does not require additional heat capacity, like heating oil or natural gas. It is a creation for CHP solution. The energy consumed during the process is the electricity for the input to conveyor, fan and motor.

This dehumidification dryer is equivalent to the combination of dehumidification waste-heat exchanger and mesh belt conveyor (playing the role of sludge placement).

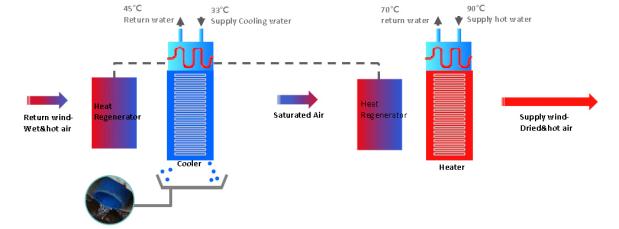

Dehumidification waste-heat exchanger

Dehumidification waste-heat exchanger is like dehumidification heat pump. It utilizes refrigeration system to cool and dehumidify hot and wet air. The Cooler plays the role as evaporator of heat pump, while the Heater plays the role as condenser. The Heater provides the supply air with drying thermal, while the Cooler provides the moisture steam with cold source for condensation.

The Heater gets the thermal from 90℃water, while the Cooler gets the cold source from 33℃water.

SHS Series is the new generation of waste heat belt dryer.

If you want to know the field application of a certain model, you can copy the product model and search in search bar.

Common Technical Specs

- Standard Heat-supplied conditions: 85?/65? (hot water, steam, etc.)

- Standard drying temperature: 48~60?(return air)/68~85?(supply air)

- Standard Cooling Condition: 33?/45?(cooling water)(?t=12?)

- Control System: Touch screen + PLC programmable controller

- SHS20000WHD

- SHS30000WHD

- SHS40000WHD

- SHS50000WHD

- SHS60000WHD

- SHS70000WHD

- SHS80000WHD

- SHS10000WH

- SHS15000WH

- SHS20000WH

- SHS25000WH

- SHS30000WH

- SHS35000WH

- SHS40000WH

- SHS45000WH

- SHS50000WH