- Home

- Companies

- Equipment Manufacturing Company (EMC)

- Products

- EMC Water Eater - Model 375G - ...

EMC Water Eater - Model 375G -Wastewater Evaporator

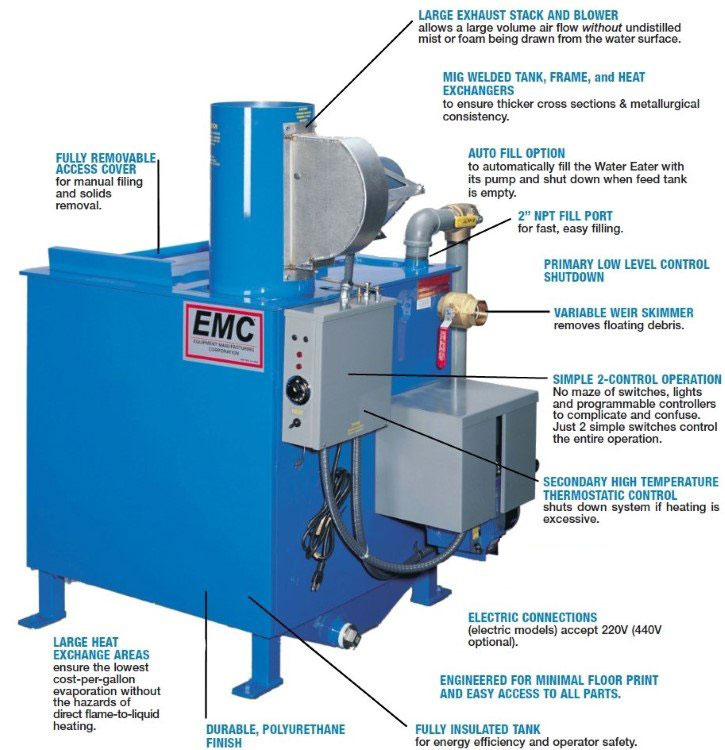

The Model 375G is a natural gas or propane heated waste water evaporator. It is available in two models, the Model 375G Carbon Steel version and the Model 375G-SS 316L Stainless Steel version (tank, floor, lid, covers, and stack are 316L SS). Installation is easy consisting of only a 120V electrical hookup, a 16" diameter vent stack, and a 3/4" standard pressure gas line.

- 40 GPH

- Natural Gas/Propane Heat

- 375 Gallon Capacity

- Carbon Steel - $26,995

- Stainless Steel - $29,995

The unit can be filled three different ways: (1) Using the supplied 2" coupling on the top of the unit; (2) Remove the lid and manually pour in fluid; or (3) Using the optional 70 GPM self priming fill pump. After an initial heat up time of approximately one hour, the Model 375G will evaporate 40 gallons per hour of water. The Model 375G will automatically shut itself down via a low level control. A secondary high temperature shutoff is also provided. When a cycle is completed the waste material can either be drained or vacuumed out of the unit through the removable lid, with a wet/dry vacuum or pump, or, if it is a solid material, scooped out. To facilitate cleanout, the interior tank of the 375G is sloped towards the 2" outlet. The "U" shape burner tube is located around the perimeter of the process tank allowing access between the tubes. The 375G water evaporator will automatically shut itself down via a low level control. A secondary high temperature shutoff is also provided. When a cycle is completed the waste material can either be drained via a 2" drain opening, vacuumed out of the unit through the removable lid, with a wet/dry vacuum or pump, or, if it is a solid material, scooped out.

- EVAPORATION RATE: 40 Gallons / Hour

- TANK CAPACITY: 375 Gallons

- TANK CONSTRUCTION: 12 Gauge Tank w/ 1" Insulation, 16 Gauge Painted Exterior

- TANK HEIGHT: 54"

- SKIMMER: Adjustable Weir Ball Valve

- TANK FILL PORT: 2" NPT Coupling

- HEATING SYSTEM: Gas: Natural Gas or Propane, 400,000 BTU, 381" x 6½" Heat Exchanger

- DIMENSIONS(FLOOR SPACE): 73" L x 35" W x 77" H, 73 L x 41" W x 77" H (with Pump/AFS)

- UTILITY REQUIREMENTS: 3/4" Gas Line, 7" to 14" W.C. 120 VAC/21Amp/1 Phase

- DRAIN: Funnel Floor, 2" Drain with Plug

- VENT STACK: 16" Diameter

- SHIPPING WEIGHT: 1100 Lbs.

- WARRANTY: One Year Parts & Workmanship. Labor & Corrosion excluded.

- Heavy Duty 12 Gauge Tank, Covers, & Stack (Carbon or 316L Stainless Steel).

- Adjustable Burner (Natural Gas or Propane) with electronic ignition, flame rectification system, and air pressure sensor.

- Automatic Shutoffs (Low Level Control & High Temperature Shutdown) for unattended operation.

- Simple one button ON/OFF operation.

- Removable Lid and obstruction free tank floor for fast and easy cleanout.

- Fully Insulated Tank.

- Variable Weir skimmer standard on all units.

- Power exhaust allows venting to outdoors.

- Quality polyurethane finish.

- Easily installed requiring only a vent stack and electrical hookup.

- Industry Standardized Components.Most parts are available from major industrial supply houses. You are not held hostage by high mark up on “captive” parts only available by the original equipment manufacturer.

- Optional 70 GPM Self Priming Feed Pump

- Optional Auto Fill System

- One Year Warranty on Parts & Workmanship

Water Eater®

Why the Water Eater® Wastewater Evaporator?

Evaporation is the simplest and most cost effective method for minimizing a wide variety of industrial water-based waste streams. It has been approved by many regulatory agencies around the country as a safe and accepted method for on-site wastewater minimization. EMC®, with the experience gained from over 20 years of manufacturing experience and thousands of systems in the field, is the industry leader in providing high value, reliable, and easy-to-operate wastewater evaporators. All EMC® Water Eaters come with the following standard features.

HEAVY DUTY CONSTRUCTION

The harsh environment inside a wastewater evaporator requires that only heavy gauge materials be used. All tanks (Carbon and 316L Stainless Steel) are of MIG welded, 12 gauge steel construction (316L Stainless steel units also have covers, lid, and vent stack of stainless steel). The top tank frame, which provides rigidity and support, is of solid 3/8" steel plate. The electrically heated Model 85E also has a 3/8" solid steel plate floor/heat exchanger. All exterior sheet metal is 16 gauge painted steel.

EASE OF CLEANOUT

The largest operating cost of a water evaporator (which other evaporator manufacturers do not like to discuss) is the maintenance time required to clean the sludge and/or concentrate from the system. Being well aware of this from our many years of manufacturing experience, ease of cleanout was a primary concern in the design. To minimize cleanout time, a fully removable cover is provided that allows for complete access to the entire tank. Next, most Water Eaters have a low top frame height which allows easy access without the need for footstools or stands. The electric units, have an obstruction free floor with a 2" step down drain port for draining free flowing fluids.

SAFETY SHUTDOWNS

All Water Eater® water evaporators have redundant shutdown systems. The primary shutdown is a low level displacement switch that deactivates the heating system when the fluid level reaches a point just above the heat exchanger surface. The secondary shutdown is a thermostat controlled sensor that measures the temperature of the heat exchanger surface and/or water temperature.

ENERGY EFFICIENCY

As the volume of wastewater increases, the energy costs of evaporation rise accordingly. Of course, all of our water evaporator tanks are fully insulated to further increase the efficiency and safety of the system.

SPARE PARTS

Wherever possible, industry standardized, off the shelf components are used. A conscious effort is made to utilize parts that can be purchased through local industrial supply houses such as Grainger or McMaster Carr. Your company is not held hostage by the high mark up "captive" parts that can only be purchased from the original equipment manufacturer.

Equipment Manufacturing Company (EMC®) manufactures two electrically heated wastewater evaporators. Electric waste evaporators are simple to install and operate needing only an electrical connection and water vapor exhaust stack.

The Model 85E evaporates approximately five gallons of water per hour and has an 85 gallon holding tank. It is through floor heated and uses strip heating elements attached to the underside of the floor. This makes the 85E easy to clean out and able to evaporate almost all of the water in the fluid. The 85E is normally recommended if you have less than 50 gallons per day of water to dispose of.

The Model 125E evaporates approximately twelve gallons of water per hour and has a 125 gallon holding tank. It uses immersion elements that directly heat the fluid. The Model 125E is useful for applications that need a higher evaporation rate and do not have access to natural gas or propane.

The electric heated Water Eaters (Models 85E and 125E) are available for operation on 480 Volt power. (Also, the Model 85E can be field converted to operate on 240V/1/50A).