- Home

- Companies

- Apoaqua Group

- Products

- Apoaqua - Model ApoPro-XJF - Wastewater ...

Apoaqua - Model ApoPro-XJF -Wastewater Screw Press

A large amount of residual activated sludge is produced during the biochemical treatment of rubber production wastewater. This sludge needs to be discharged from the system in time, otherwise the consumption of dissolved oxygen will be too high and the treatment efficiency will decrease. At the same time, the suspended solids in the effluent of the secondary sedimentation tank increase. In severe cases, it can lead to the disintegration of sludge in the system due to endogenous respiration. As a result, new soluble CODCr was formed. This affects the final effluent of the system to meet the discharge standards. The remaining activated sludge is generally disposed of through gravity concentration, chemical conditioning, and press filtration into mud cake. and then transported or otherwise disposed of.

At present, wastewater treatment plants generally use plate and frame filter presses, belt filter presses, and centrifugal dehydrators to filter the remaining activated sludge. The drawbacks of the first two methods are low filtration efficiency and high energy consumption. As a result, the filter cloth is prone to clogging and difficult to clean. The centrifugal dehydrator makes relatively loud noise and has a poor working environment. For some sludge filter presses with special properties such as high viscosity or oiliness, the above three types of filter presses are difficult to function. The new sludge dewatering machine has the characteristics of low energy consumption, low noise, easy operation, and the equipment is not easy to block. It also has a self-cleaning function and is especially suitable for press filtering of sticky sludge. We have verified the excellent performance of ApoPro-XJF wastewater sludge dewatering equipment through on-site pilot tests and industrial tests.

Comparison Between Sludge Dewatering Machine and Traditional Filter Press

Plate and frame filters and belt filters that use filter cloth as the filter medium utilize the squeezing force exerted on the mud cake during filtration. This achieves the separation of rubber sludge particles from free water. The dewatering effect is related to the applied pressure and time. The force direction of the mud cake is opposite to the direction of dewatering flow. The advantage is good dehydration effect, but the disadvantage is that the filter cloth is prone to clogging. The filter press clogging of sludge containing oil or colloid is more serious.

Centrifugal dehydration uses centrifugal force acting on sludge to separate sludge particles and free water. The dewatering effect is related to the density difference between sludge particles and water. The force direction of the mud cake is perpendicular to the dewatering flow direction, which is 90°. The disadvantage is that when the density difference between sludge particles and water is small, there is high noise, high energy consumption, and poor dewatering effect. Fine particles accumulate inside the filter to form a dense layer, increasing the separation resistance of free water. It is not suitable for pressure filtration of viscous sludge.

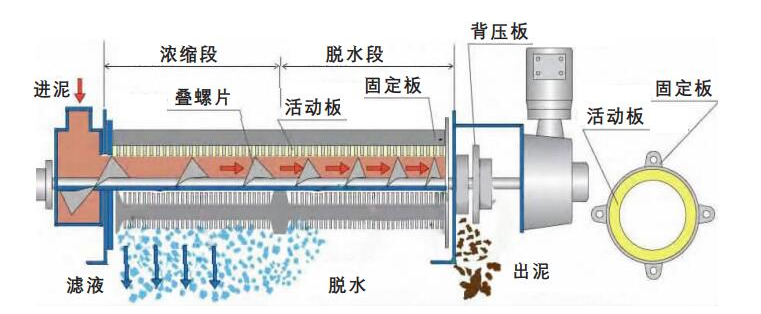

The structure and working principle of ApoPro-XJF rubber sludge dewatering equipment are shown in Figure 2.

- The mixed liquid flows into the filter cartridge of the sludge dewatering machine through the feed port. The filter cartridge is assembled alternately from fixed ring plates and movable ring plates.

- The material moves towards the discharge port under the driving force of the screw auger. As the pitch between the spiral augers gradually decreases, the pressure on the rubber sewage sludge also gradually increases. Dehydration begins under the action of pressure difference, and free water flows out from the filter gap between the movable ring and the fixed ring.

- The diameter of the spiral auger is larger than the hole diameter of the movable ring. When the spiral auger rotates, it drives the movable ring to rotate together. The machine relies on the relative movement between the movable ring and the fixed ring to achieve the self-cleaning function. To prevent blockage, the mud cake is completely dehydrated under the push of the spiral shaft.

- Because there is always relative motion between the fixed ring and the movable ring. Therefore, there are always some small rubber sludge particles that are squeezed out from the gaps with the water. In order to prevent overflow sludge particles from settling on the surface of the filter barrel, an automatic water spray flushing system is installed. Spray clean the filter cartridge surface regularly to keep the filter cartridge surface clean.

- The gap between the fixed ring and the movable ring is fixed and cannot be adjusted arbitrarily. The moisture content of the filter press mud cake can be adjusted by adjusting the gap and feed volume of the back pressure plate.

ApoPro-XJF sludge dewatering machine adopts the principle of thin layer dewatering. Each time, the mechanical force only acts on a thin layer of mud cake. Thus, the free water in the sludge can be separated from the sludge at the shortest distance and fastest speed. The force direction of the mud cake is the same as the flow direction of the water, which is 0°. Therefore, the energy consumption of the sludge dewatering machine is low. The sludge dewatering machine has a cylindrical structure. Therefore, one or more parallel units can be selected based on the amount of material being processed. ApoPro-XJF sludge dewatering machine has a self-cleaning function and is especially suitable for press filtering of sticky sludge.

- ApoPro-XJF sludge dewatering machine has good adaptability to sticky sludge containing colloidal particles. The equipment is not easy to block and easy to maintain. It has the characteristics of low energy consumption, low noise and easy operation.

- Industrial application test results show that the ApoPro-XJF sludge dewatering machine can press the remaining sludge from the rubber wastewater treatment system into a mud cake with a moisture content of 86%, which meets the requirements for outbound transportation and disposal.