- Home

- Companies

- Apoaqua Group

- Products

- Apoaqua - Model ApoBlu-YQT - Wastewater ...

Apoaqua - Model ApoBlu-YQT -Wastewater Screw Press

In industrial spray shops (automotive and many other spray booths). Some of the paint escapes into the surrounding air as a mist. After a while, removing these contaminants becomes necessary. The most common method is to replace the air with water. Under the action of water, paint particles aggregate to form sludge. The resulting paint sludge is removed from the spray booth using a pump system.

What is paint sludge?

Paint sludge contains certain toxicity, mainly including the following substances:

- Organic matter. Containing organic compounds such as phenols, aldehydes, and amines, making wastewater highly toxic and flammable.

- Heavy metal. The heavy metals such as chromium, cadmium, and lead contained in it are harmful to the environment and human health.

- Dissolved solids. Contains many suspended particles and solid particles, which have a certain impact on the water environment.

If someone asks: Is paint sludge hazardous? The answer is a resounding yes. Therefore, paint sludge treatment is very necessary.

ApoBlu-YQT Paint Wastewater Screw Press Dewatering Guide

How to remove paint sludge?

When you look at the chemical composition of paint, you’ll find that its wastewater and sludge need to be disposed of as hazardous waste. Among the many types of sludge dewatering processes, paint sludge treatment is a difficult task. Many people have proposed using centrifuges to complete the job, but it turns out that this solution cannot meet the challenges of paint sludge dewatering.

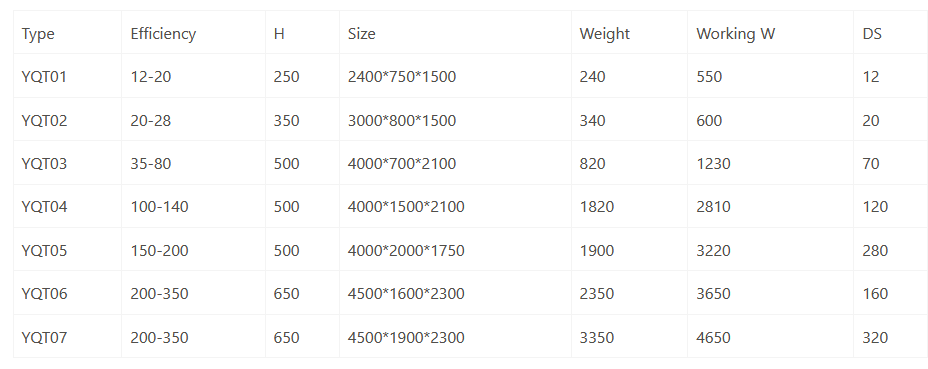

For this purpose we developed ApoBlu-YQT paint screw press dewatering. This series of dehydration equipment can solve most of the problems. Currently, it is the best solution for efficient treatment of paint sludge.

Common Problem

Some customers often encounter problems when using paint wastewater screw press dewatering machine. The most common problem is that the dehydrated paint sludge still has high water content. The following are possible reasons.

- The feed concentration is high.

Reasonable calculation and control of feed concentration should not be too large. If the concentration is too high, it will easily lead to filter press concentration. Natural paint sludge will be very thin or even sludge-free.

Solution: Entrust the manufacturer to set, debug, scientifically calculate, and adjust the feed concentration and quantity. - Flocculant problem.

The screw press dewatering machine is a piece of equipment that requires high flocculants. The choice of flocculant has a great impact on the sludge discharge efficiency of the equipment.

Solution: Choose the appropriate flocculant. If you don’t know the type of flocculant, you can contact the manufacturer to send samples for testing. - Spindle speed and stirring speed.

The rotation speed of the shaft and the mixing speed of the coagulation mixing tank cannot be too fast or too slow. Because too fast can easily lead to insufficient mixing.

Solution: Check whether the stirring speed is within a reasonable range (the speed of the screw press auger is generally 2 revolutions, and usually does not need to be adjusted). - Blockage problem.

Check if there is any blockage and if there is any locking status. Clogging will seriously affect the sludge dewatering efficiency of the sludge dewatering machine.

Solution: If you encounter a blockage, flush it with plenty of water. And adjust the water spray system parameters or turn the screws to solve the problem (staff guidance is required).

- The structure is simple and the failure rate is low.

- Maintenance method is simple and efficient.

- Wearable parts are treated with wear resistance.

- The model is small and does not take up space.

- lower polymer dosing consumption in paint sludge.

After being processed by the ApoBlu-YQT sludge dewatering system, the paint sludge volume is approximately 10% of the original volume.

Another feature of ApoBlu-YQT sludge dewatering equipment is its simple and sturdy structure. most sludge dewatering machine suppliers fall into the misunderstanding of meaninglessly complicating the equipment. Adding useless workpieces greatly increases the failure rate. On the basis of ensuring efficient work efficiency, our equipment pays more attention to work stability.