- Home

- Companies

- Kopay Enviroment Technology

- Products

- Kopay - Model KPSDC-XS - Wastewater ...

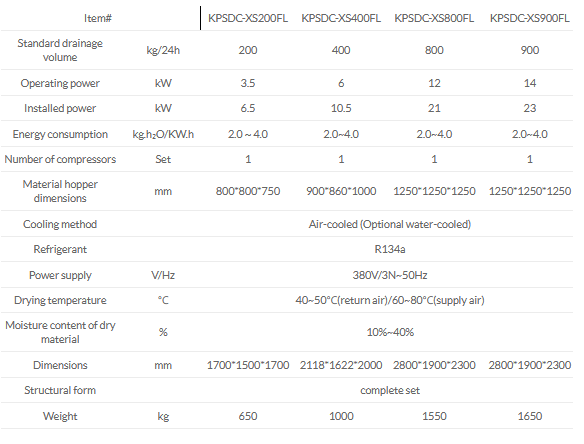

Kopay - Model KPSDC-XS -Wastewater Sludge Dryer

Low-temperature sludge drying equipment (also know for container type sludge dryer). This dryer is capable of directly drying sewage or sludge with a moisture content of 83% to a dry sludge with a moisture content of 10%-30%, reducing volume by up to 90% and achieving up to 90% effective sterilization. It features low energy consumption, no pollution, and is widely used in the drying and reduction of municipal sludge and industrial sludge (such as dyeing, papermaking, electroplating, chemical, leather, pharmaceuticals, etc.). The dry sludge with a moisture content of 10%-30% can be further processed into harmless resources such as gasification, co-incineration, composting, or building materials. Mainly according to the applications, there are container type sludge dryer.

- The moisture content of the dried sludge can be adjusted to between 10% and 50%, with reduction rates exceeding 80%.

- No risk of odor leakage, ensuring a clean working environment without the need for expensive odor control systems.

- Direct installation within the facility is possible, allowing for centralized sludge disposal. Additionally, condensate water can be discharged directly without secondary treatment.

- Efficiently dries wet sludge with an initial moisture content of 83% to a moisture content of 30%. Operating costs are as low as 180 kWh per ton

- Achieves a comprehensive dehumidification performance ratio of over 4.2 kg of water per kWh. This exceeds industry standards by double the efficiency, with energy savings up to 50% compared to traditional low-temperature drying methods.

- Fully enclosed system and incorporates heat pump heat recovery technology, ensuring zero heat loss and maximizing thermal efficiency.

- Operating at a low temperature range of 40-75°C within a fully enclosed system, our process ensures safety with no dust hazards. With oxygen content below 12% and dust concentration below 60g/m³ during the drying process, there’s no risk of dust emissions or explosion hazards. Additionally, the discharge temperature is below 50°C, eliminating the need for secondary cooling and enabling direct storage