Komax Omega - Model 740/750 -Wire Harnesses Assembly Machine

The Omega 740/750 wire assembly machine can be used to produce wire harnesses of various complexity and to equip them with terminal housings on one or both sides. Depending on the design, five (Omega 740) or eight (Omega 750) modules can be installed. This means that autonomous wire harnesses can be created in a short production time. The Omega series is manufactured for automated wire harness production. Regardless of the operator, the quality of the end product is ensured: A high-precision force sensor monitors the insertion process of up to 36 different wires and the precise locking of the terminal part in the housing. The individual parameters are automatically compared. Supported by a spindle drive, even the smallest components are loaded that could hardly be connected in by hand. The optionally available ACD incision monitoring additionally ensures quality.

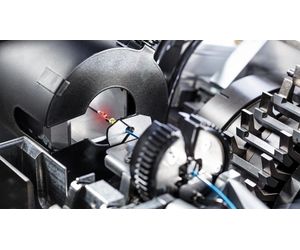

Optical terminal measuring system for insertion of various terminals

The optical terminal measuring system enables insertion of a wide variety of terminals into terminal housings, on one side as well as on both sides.

The automatic wire changer provides up to 36 wires from the entire cross-sectional area. This covers, for instance, the wide variety of control cabinet designs.

The already integrated three blade pairs with optional incision monitoring (ACD) cover a cross-section range of 0.13 to 2.5 mm² (AWG 26–14).

Unwound wires always have a twist. The untwisting module removes the twist from the wires, which is important for subsequent fully automatic loading.

Two-sided wire harnesses with a high level of complexity can be easily produced with the help of the wire storage. It also enables the immediate post-production of defective wires.

Omega 740

Metric

- Shortest wire length for one-sided processing: 240 mm

- Shortest wire length, double-sided jumper connection: 300 mm

- Shortest wire length, double-sided jumper connection max.: 540 mm

- Shortest wire length, complex loading min.: 300 mm

- Shortest wire length, complex loading max.: 760 mm

- Wire length (standard tray) max.: 3000 mm

- Strip length side 2 max.: 25 mm

- Strip length side 1 max.: 25 mm

- Wire outer diameter max.: 4 mm

- Wire cross section min.: 0.13 mm²

- Wire cross section max.: 2.5 mm²

- Wire draw-in speed max.: 10 m/s

- Wire acceleration: 50 m/s²

- Cycle time per loading: 1.8 – 2.6 s

- Length accuracy: ± 1mm or < 0.2% (depending on cable length)

- Noise level (without crimp modules) max.: 75 dB

- Electrical connection: 3 × 208 - 480 V 50/60 Hz, 4 kVA (base machine)

- Compressed-air connection: 5 – 8 bar

- Air consumption (without modules): 15 m³/h

- Network connection: Ethernet

- Exhaust connection: Upon request

- Recommended operating pressure ±0.5bar/7.25psi: 6 bar

- Operation outside the recommended operating pressure: Non-compliance with the recommended operating pressure can restrict the proper functioning of peripheral devices. Please also observe the technical data for peripheral devices.

- Compressed-air quality in accordance with DIN/ISO 8573-1: Compressed air, dry, filtered (10 μm), oil-free

- Minimum permissible cross section of connection lines: DN 15

- Recommended size of compressed-air storage per machine: 50 l

- Weight (approx.): 1900 kg

- Floor load capacity: 500 kg/m²

- Maximum permissible operating pressure: 6.5 bar

- Length: 4785 mm

- Width: 2050 mm

- Height (with safety cover closed): 2060 mm

- Height (with safety cover open): 2870 mm

- Minimum clearance around equipment for maintenance work: 1500 mm

- Floor conditions: Level, stable, clean and vibration-free bearing surfaces. Bearing surface for machine bearing points, made from a continuous base plate of concrete. No expansion joints between machine bearing points. Bearing surface is slip-proof. No plastic or asphalt coatings.

- Processing outside the specifications: Processing outside the specifications upon request. In case of doubt, we will be happy to provide processing samples for your wires.

Imperial

- Shortest wire length for one-sided processing: 9.45 in

- Shortest wire length, double-sided jumper connection: 11.81 in

- Shortest wire length, double-sided jumper connection max.: 21.26 in

- Shortest wire length, complex loading min.: 11.81 in

- Shortest wire length, complex loading max.: 30 in

- Wire length (standard tray) max.: 118.11 in

- Strip length side 2 max.: 0.98 in

- Strip length side 1 max.: 0.98 in

- Wire outer diameter max.: 0.16 in

- Wire cross section min.: AWG26

- Wire cross section max.: AWG14

- Wire draw-in speed max.: 33 ft/s

- Wire acceleration: 165 ft/s²

- Cycle time per loading: 1.8 – 2.6 s

- Length accuracy: ± 0.039 in or < 0.2% (depending on cable length)

- Noise level (without crimp modules) max.: 75 dB

- Electrical connection: 3 × 208 - 480 V 50/60 Hz, 4 kVA (base machine)

- Compressed-air connection: 73 – 116 psi

- Air consumption (without modules): 529.72 ft³/h

- Network connection: Ethernet

- Exhaust connection: Upon request

- Recommended operating pressure ±0.5bar/7.25psi: 87 psi

- Operation outside the recommended operating pressure: Non-compliance with the recommended operating pressure can restrict the proper functioning of peripheral devices. Please also observe the technical data for peripheral devices.

- Compressed-air quality in accordance with DIN/ISO 8573-1: Compressed air, dry, filtered (10 μm), oil-free

- Recommended size of compressed-air storage per machine: 50 l

- Weight (approx.): 4188.78 lb

- Floor load capacity: 500 kg/m²

- Maximum permissible operating pressure: 6.5 bar

- Length: 188.4 in

- Width: 80.7 in

- Height (with safety cover closed): 81.1 in

- Height (with safety cover open): 113 in

- Minimum clearance around equipment for maintenance work: 59 in

- Floor conditions: Level, stable, clean and vibration-free bearing surfaces. Bearing surface for machine bearing points, made from a continuous base plate of concrete. No expansion joints between machine bearing points. Bearing surface is slip-proof. No plastic or asphalt coatings.

- Processing outside the specifications: Processing outside the specifications upon request. In case of doubt, we will be happy to provide processing samples for your wires.