Komax CoaxCenter - Model 6000 -Wire Processing Micro-Coaxial Cables

The CoaxCenter 6000 processes micro-coaxial cables of 0.005 mm² (40 AWG), coaxial cables up to 7 mm in diameter and single conductor wires from 0.013 - 2.5 mm² (36 AWG - 14 AWG). The cut, strip, and terminate machine platform CoaxCenter 6000 can be configured with up to six processing stations. Stripping is carried out using the RotaryUnit 6000 or V-shaped blades with multi-blade heads. The cable end is held by a single gripper during all processes.Raw material with a diameter of up to 7.0 mm (0.27") can be processed with the linear feed unit at a speed of 2.5 m/s. The belt drive allows for diameters of up to 5.5 mm (0.21") and speeds up to 5 m/s.Stripped cable ends are continually monitored by the QCam 360 camera system, which can detect cut strands in the wire. Reject parts are sorted out immediately.

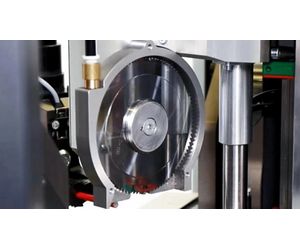

High precision rotary unit with integrated extraction system

The fast rotary unit garantees high-precision cable processing. It processes cable diameters ranging from 0.4 to 7.0 mm (0.02 – 0.27") for maximum flexibility.

Cable gripper and cable tension functions of the linear feed unit ensure unparalleled length accuracy. Lengths of 11 to 1,500 mm (0.43 – 59") are freely programmable.

The sawing unit cuts cables quickly and at a perfect right angle. The single gripper holds the cable in the correct position, ensuring that the inner conductors remain straight.

Metric

CoaxCenter 6000

- Number of processing stations max.: 6

- Wire length, processing on both sides min.: 15 mm

- Wire length, processing on both sides (optional from) min.: 9 mm

- Strip length side 1 min.: 0.1 mm

- Strip length side 1 max.: 58 mm

- Strip length side 2 min.: 0.1 mm

- Strip length side 2 max.: 38 mm

- Conductor cross section min.: 0.005 mm²

- Conductor cross section with mandatory sampling inspection max.: > 2,5 mm² (AWG14)

- Conductor cross section with mandatory sampling inspection max.: < 0,35 mm² (AWG22)

- Conductor cross section max.: 2.5 mm²

- Power source: Electric - Pneumatic

- Power supply input: 100/120 VAC, 200/240 VAC, 800 VA, 50/60Hz

- Compressed-air connection: 6 bar

- Weight: 450 kg

- Weight equipped with max. number of stations: 630 kg

- Width: 900 mm

- Length: 1722 mm

- Length conveyor belt: depending on model

- Height: 1442 mm

- Height (with safety cover open): 2347 mm

- Processing outside the specifications: Processing outside the specifications upon request. In case of doubt, we will be happy to provide processing samples for your wires.

Imperial

- Number of processing stations max.: 6

- Wire length, processing on both sides min.: 0.59 in

- Wire length, processing on both sides (optional from) min.: 0.35 in

- Strip length side 1 min.: 0.004 in

- Strip length side 1 max.: 2.28 in

- Strip length side 2 min.: 0.004 in

- Strip length side 2 max.: 38 mm

- Conductor cross section min.: 0.005 mm²

- Conductor cross section with mandatory sampling inspection max.: > 2,5 mm² (AWG14)

- Conductor cross section with mandatory sampling inspection max.: < 0,35 mm² (AWG22)

- Conductor cross section max.: 2.5 mm²

- Power source: Electric - Pneumatic

- Power supply input: 100/120 VAC, 200/240 VAC, 800 VA, 50/60Hz

- Compressed-air connection: 6 bar

- Weight: 450 kg

- Weight equipped with max. number of stations: 630 kg

- Width: 900 mm

- Length: 1722 mm

- Length conveyor belt: depending on model

- Height: 1442 mm

- Height (with safety cover open): 2347 mm

- Processing outside the specifications: Processing outside the specifications upon request. In case of doubt, we will be happy to provide processing samples for your wires.