- Home

- Companies

- WTR Engineering, LLC

- Products

- WTR-Engineering - Headworks Fine ...

WTR-Engineering - Headworks Fine Screens

WTR’s Headworks Fine Screens are one of the most cost effective means for fine screening of domestic waste water. Fine Screens are used where continuous screening is essential for protection of downstream equipment and processes. Applications include conventional waste water treatment plants [WWTP’s], advanced membrane water reclamation facilities [WRF’s] and combined stormwater overflows [CSO’s].

Debris in the flow stream can interfere with the operation of equipment such as grit removal, clarifiers, membranes, pumps and various treatment processes. Fine (circular opening) Screens are used where Coarse (slotted opening) Screens alone cannot satisfy the downstream debris removal requirements. Consideration of the treatment process used, along with review of the influent sources and flow volume, are critical to the proper selection of the type of screen, flow pattern, mesh aperture, rotation speeds and materials of construction.

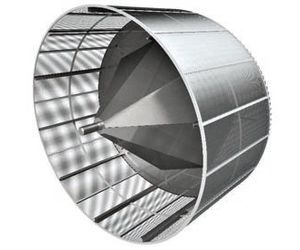

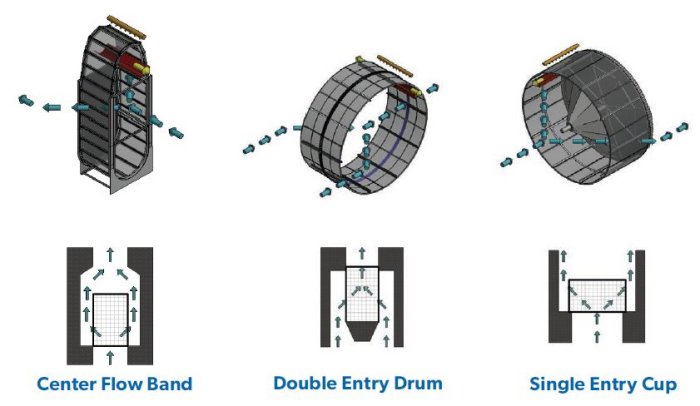

WTR’s Headworks Fine Screens are designed to automatically and reliably filter influent water and discharge recovered debris into the appropriate handling system. Screens are designed to handle waste water debris such as cotton products, identifiable floatables, fibrous materials and other miscellaneous debris common in waste water. WTR’s Headworks Fine Screens are available in various flow patterns including Center Flow Band (CFB), Double Entry Drum (DED) or Single Entry Cup (SEC).

To eliminate debris carry-over, the ‘center flow’ pattern is recommended for total separation of influent from effluent. The CFB, DED and SEC are all ‘center flow’ screens where the influent enters the center of the screen. Filtration is carried out by the rotation of the band, drum or cup and debris carry-over is completely eliminated.

Selection of the screening media is as important as the flow pattern. Thin perforated plates, wire meshes and wedge wires will ‘hair pin’ from fibrous debris. WTR’s BeeCell™ honey comb thick plate screening media prevents fibrous build up, offers a high percent open area (POA) and prevents blinding via tapered orifices. Common aperture sizes are 0.20” (5mm) for conventional WWTP’s and 0.08” (2mm) for membrane WRF’s. Options for finer apertures are available.

COMMON FOR CENTER FLOW, DRUM SCREEN AND CUP SCREEN

- Screens are built to specific conditions for flow, influent sources, mesh aperture, water depths and debris discharge requirements.

- BeeCell screening media offers a high open area of thick polyurethane to prevent hair-pinning and corrosion.

- Frame materials of mainly Carbon Steel (epoxy coated) or Stainless Steel (304L, 316L, Duplex or other).

- Main structure end seals of Neoprene & UHMW prevent bypassing of debris larger than the mesh aperture.

- Variable Frequency Drive (VFD) motors incorporate multiple speeds to provide flexibility during varying flow conditions.

- Shaft mounted drives reduce maintenance and eliminate drive sprockets, chains and cumbersome chain guards.

- Dual spray headers provide positive overlapping coverage and reduces pressure and volume for cleaning.

- Main shafts utilize anti-friction bearings for reliable continuous operation and reduction in maintenance requirements.

CENTER FLOW BAND SCREENS

- Adaptable to existing channels via upstream flow diverters and varying guide arrangements.

- Individual high strength mesh panel support frames handle high differentials.

- Sealing between panels via flexible neoprene or hinged arrangement.

- Oversized water lubricated carrier chain rollers reduce horsepower and extend chain life.

- Reduced height head section allows for routine inspection and maintenance accessibility.

- Solid rear plate provides free standing design and can accommodate integral overflow.

- Roll around boot section delivers positive tracking and includes replaceable wear tracks.

DOUBLE ENTRY DRUM SCREENS

- Extremely reliable operating performance due to simplified circular structure.

- High strength frame design allows for operation under extreme flow conditions.

- Large submerged surface area accommodates high variations in flow and levels.

- Low maintenance with no permanent rotating components below water level.

- Extended debris elevators handle oversized or unusual shaped debris.

- Positive rotation via (cast iron or nylon) gear rack and drive pinion.

- Access platform with ladder and railing for wash water jet inspection.

SINGLE ENTRY CUP SCREENS

- Simplified civil works or structural frame support for ‘drop in’ guided arrangement.

- Solid internal downstream back provides high strength frame with no bypassing.

- Extremely reliable operating performance due to simplified circular structure.

- Low maintenance with no permanent rotating components below water level.

- Extended debris elevators handle oversized or unusual shaped debris.

- Positive rotation via (cast iron or nylon) gear rack and drive pinion.

- Access platform with ladder and railing for wash water jet inspection.