- Home

- Companies

- Conifer Systems

- Services

- Conifer Systems - Aftermarket Services

Conifer Systems - Aftermarket Services

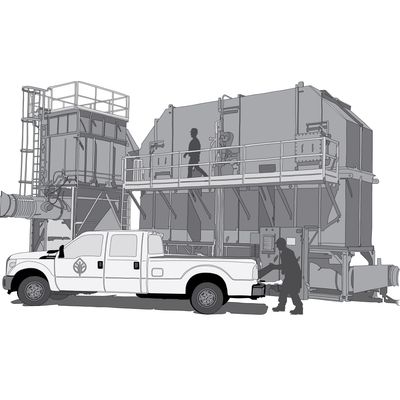

Our preventative maintenance and service includes regularly scheduled service and maintenance, added support and care, as well as a full list of customizable service options focused on improving the uptime of your equipment. With nearly two decades of supporting industry leaders in manufacturing, we can adapt our expertise to serve a multitude of plant assets in their unique manufacturing environments. Our evaluation includes a full internal and external inspection by our field service professionals. Our team will review operating data, process conditions, the system’s maintenance log and will perform a 200-point inspection. Conifer Systems’ personnel will make minor repairs, calibrate instrumentations as needed and perform any other necessary preventative maintenance. We will provide a detailed log of the work performed during the evaluation including inspection findings and recommendations.

Over time, systems need to be maintained. RTOs and RCOs may experience reduced airflow capacity, channeling or voids in their media beds, thermal imbalances, become less energy-efficient and take longer to start up. Any of these challenges typically indicate it’s time for a media replacement.

Our team, which has knowledge and experience with all makers of equipment, can evaluate your system and provide the media replacement solution that will reinstate optimum operating conditions which can reduce operating costs.

Conifer Systems offers our customers a complete line of emissions control equipment parts for thermal oxidizers, scrubbers, flares, carbon adsorbers, rotor concentrators and more, from any manufacturer.

Conifer Systems Can:

- Do custom modifications. We understand that one size does not fit all.

- Work with corrosive operating conditions. Our in-house manufacturing operation has experience with a variety of materials, including multiple grades of stainless steel and mild steel.

- Create discontinued parts. If a part you need was discontinued by other manufacturers, we can make it.

- Fulfill emergency orders. Our warehouse stocks hundreds of items that can quickly be drop-shipped.

- Help fill your warehouse. Our team can assist you with creating a recommended parts list specifically for your equipment.

While we stock hundreds of pollution control equipment parts, some components have very long lead times. Please contact us to create a plan to ensure you have parts for your equipment stocked in your warehouse.

We understand that a new emissions control system can be costly, which is why Conifer Systems specializes in upgrades, retrofits, relocations and offers previously owned equipment. Our engineering and service teams can provide solutions for systems by any manufacturer.

Upgrading or retrofitting equipment can lower energy costs, improve VOC destruction efficiencies, increase product throughput and reduce emissions of other pollutants. Some of our most popular projects include installing a higher efficiency heat exchanger, adding variable frequency drives to fans, improving process flow and distribution, integrating secondary heat recovery and balancing combustion systems. Older systems can also be replaced with newer, more energy-efficient units that take up less space.

Maintenance emergencies and repairs happen. Conifer can help. Our engineers, skilled manufacturing team and service technicians will help limit your system’s downtime. Whether it’s a single part, a retrofit or an upgrade, we are here for all your needs.

Have an Emergency? Call us now: (936) 446-0020