Emissions.

Emission (lit. sending out) is the term used to describe the discharge of pollutants to the air, ground and water. In order to reduce environmental pollution by emissions, stringent limits have been prescribed in the Technical Instructions on Air Quality Control (TA Luft) by the German Federal Immission Control Act (BImSchG). This represents a significant environmental protection objective. Maximum limitation of environmental pollution as a result of incineration and co-incineration of waste throughout Europe, is the aim of the new guideline 2000/76/EC. The guideline specifically defines certain operating conditions, special technical equipment requirements and emission limits.Obtaining permission to build a waste incineration plant is subject to adherence to limit values for all pollutants as prescribed by the responsible regulatory authority. These may vary from municipality to municipality. Authorities may for instance make an approval conditional to fulfilment of half the value prescribed by the 17th Directive of Germany`s Federal Immission Control Act (17. BImSchV).

As an incineration plant operator, EEW Energy from Waste is committed to ensure adherence to the limit values specified in the notice of approval. This includes constant monitoring of the maximum permitted capacity of the installed flue gas cleaning system by means of continuous measurements.

What should be measured and how, is prescribed by law. The suitability of the equipment used for measurement is also verified. Additionally required are an annual functional test and calibration by a registered measurement institute. The equipment is moreover maintained by the operator and subjected to six-monthly inspections by the manufacturer.

Transparency of the measurements is guaranteed, in the sense that constant transmission of the data collected at the point of emission to the responsible regulatory authority via a data line makes the data publicly available at any time.

Emission measurements are differentiated into two types: continuous measurements and single measurements.

Continuous measurement involves meticulous recording of the values. For this purpose, a measuring station is installed immediately in front of the chimney, from where the collected values are transmitted to an emissions calculation computer via a data system. The computer calculates half-hourly and daily average values. These average values are transmitted to the responsible supervisory body by data line.

The 17th Directive of Germany`s Federal Immission Control Act (17. BImSchV) defines exactly which limits the collected data may not exceed. In addition, the regulatory authority may prescribe an even lower limit value.

Continuous measurement mainly involves constantly checking the following components:

All heavy metal compounds, dioxins and furans are measured by means of single readings. These compounds are documented every two months in the first year after putting a plant into service and every year after that.

Combustion Parameter.

Another important measurement value is the combustion parameter. This fulfils two functions: it ensures that the minimum temperature in the combustion chamber is at least 850°C at all times, and that the pollutants remain at this temperature for at least two seconds. This is important because dioxins and furans are only definitely destroyed under these conditions.

To guarantee this, the measuring equipment is calibrated by the Technical Inspection Agency (TÜV) after commissioning of the plant. The data are constantly recorded and stored in the emissions calculation computer and the control system from after this procedure. This safeguards a constant incineration temperature of over 850°C.

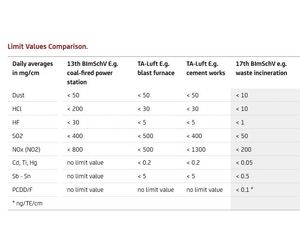

With regard to emission limit values, all incineration plants in Germany - including for example also power plants and blast furnaces - are subject to different legal regulations.

TA-Luft = Technical Instructions on Air Quality Control

BImSchV = Directive of Germany`s Federal Immission Control Act