- Home

- Companies

- Food Safety Analytics

- Services

- Food Safety & QA Services

Food Safety & QA Services

Flavorbase takes extensive measures to ensure its high quality products are produced in safe and sanitary manner. Our company operates under state and federal inspections, and has implemented Sanitation Standard Operating Procedures (SSOP) and Hazard Analysis and Critical Control Point (HACCP) programs.

Our HACCP program is a logical, scientific approach to controlling potential safety problems with respect to our food production. We have defined procedures in our manufacturing process to prevent, eliminate, or reduce to acceptable levels all potential biological, chemical and physical food safety hazards. In addition, we have established procedures for using the results of a frequent monitoring program to adjust any process as needed, in order to maintain control. Our monitoring consists of planned sequence of observations or measurements to assess the efficacy of our controls and to produce an accurate record for future use in verification. If an unacceptable deviation occurs, we have in place corrective actions procedures that are followed without exception. We also have established effective record-keeping procedures that document our HACCP systems. Documentation includes:

- SSOP Records and employee training.

- HACCP Plan and reassessments.

- Operating records of Critical Limits.

HACCP Program Key Elements include:

- Guidelines in the areas of Personnel, Buildings and Facilities, Equipment and Utensils, as well as Production and Process Control to provide a safe practice for manufacturing, packaging, and storage of our products.

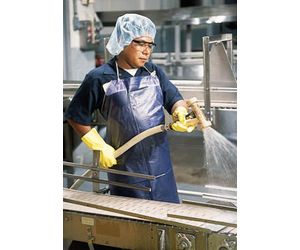

- Written procedures for cleaning our production equipment.

- A Plan for minimization of Critical Control Points.

Sanitation Standard Operating Procedures (SSOP) Key Elements include:

- A written document describing daily sanitation procedures that our plant conducts before and during operations to prevent direct contamination or adulteration of products.

- Procedures our plant conducts each day prior to the start of operations. These procedures address the cleaning of food contact surfaces, equipment, and utensils. The frequency of each procedure is specified.

- Follow up procedures to ensure on-site supervisors sign, date and document verification of the performance of our food safety plan.

Food Safety Areas of Focus include:

- GMP: We apply Good Manufacturing Practices (GMP) and have in place basic environmental and operating conditions that are necessary for the production of safe, wholesome food.

- Supplier Control: We have in place a Supplier Control program to ensure that our suppliers have in place effective GMP and food-safety programs. We require written specifications for all ingredients, products, and packaging materials.

- Production Equipment: All of our production equipment is constructed and installed according to sanitary design principles. Preventive maintenance and calibration schedules have been established and documented.

- Training: All of our employees receive documented training in personal hygiene, GMP, cleaning and sanitation procedures, personal safety, and their role in the HACCP program.

- Receiving, Storage, and Shipping: All raw materials and products are stored under sanitary conditions and the proper environmental conditions with respect to temperature and humidity to assure their safety and wholesomeness.

- Traceability and Recall: All raw materials and finished products are lot-coded and a recall system is in place so that rapid and complete traces and recalls can be done when a product retrieval is necessary.

- Chemical Program: We have documented procedures are in place to ensure segregation and proper use of nonfood chemicals in the plant.

- Pest Control: We have in place an effective pest control programs.

Quality Assurance At Flavorbase: At Flavorbase, we take quality assurance very seriously. We emphasize delivering quality products to our customers on a consistent basis. In any operation, a number of factors, including human error, may impact production. Our testing processes are designed to catch any potential mistakes before the product leaves our plant. The Flavorbase facility is home to two onsite laboratories that are valuable instruments in our Quality Assurance (“QA”) program. One of our onsite labs is operated by Food Safety Analytics (“FSAL”), a professional analytical laboratory company providing services to a number of food processors operating in the Central Valley. All laboratory technicians work under the supervision of a Dr. Naga Lakshmanan, a PhD in Microbiology.

- FSAL Microbial Analysis: The following microbial analyses are routinely performed on products manufactured, before and after processing, on a random sampling basis: total aerobic plate counts, yeasts and molds, staph, listeria, E. coli and coliforms.

- Shelf-life studies: Shelf-life study is normally performed every 30 days for periods of six to twelve months. For accelerated shelf-life study, the samples are incubated at 38°C and samples are taken every week to analyze. Accelerated studies are completed in four to six weeks. Shelf-life studies involve standard, microbial, chemical and sensory analyses.

- Nutritional Chemistry: Chemistry analysis measures proteins, fats, lipids, carbohydrates, water activity, minerals and vitamins.

- Water analysis: Water comes into the plant is monitored for microbial contents, pH, salinity, and hardness on a daily basis.Physical Properties are measured and compared to control samples from every production batch. We have provided additonal content regarding our measurements below for the benefit of retail customers that may be less familar with these terms:

- pH measures the acidity or alkalinity of a sample and is expressed on the pH scale of 0-14, with 7 being neutral (water). Different ingredients have different levels of acidity: Table Vinegar, or acetic acid, typically has a pH of 3, Coconut Milk has a pH of 6.5, while Eggs have a pH of 7.8. Lower acid foods are less likely to spoil. A pH measurement is frequently used to determine the ripeness of certain fruits and vegetables, including tomatoes. Since the flavors of certain raw ingredients change with changes in pH, measuring the pH of a finished product can be an important quality control check.

- Brix is a measure of the sugar content of a liquid solution. One degree Brix (°Bx) corresponds to 1 gram of sucrose in 100 grams of liquid. If the solution contains dissolved solids other than pure sucrose, such as other sugars, minerals etc., then the °Bx measures only the dissolved solid content. The evaporation of water resulting from preparation of a reduction sauce serves to concentrate the flavor in the sauce. This flavor concentration can be measured precisely using a refractometer and expressed in degrees of Brix. Brix has long been used in the wine, sugar, fruit juice, honey and other beverage industries. We find that it is particularly useful in quality control applications when evaluating the concentration of sugar and solids in our finished products.

- Viscosity is a measure of thickness, or pourability. Thus, water is “thin”, having a lower viscosity, while honey is “thick”, having a higher viscosity. Put simply, the less viscous the fluid is, the greater its ease of movement. Why is viscosity important? A barbeque sauce must pour out of a squeeze bottle easily and coat food without running off. Cream filling in a doughnut needs to hold in place when you bite into it and not squirt out. Salad dressing is better appreciated when it coats the lettuce and vegetables and doesn’t run off into the bottom of the bowl. The icing on a cake must hold its shape – especially on the sides where sag can become a problem or on top where decorative styling is important. These instances show why a viscosity test is valuable in the quality control lab to identify batches of product that do not meet the desired performance and appearance standards expected by our customers.

- Color is measured with a colorimeter, which measures the three primary color components of light which are seen by the human eye. Spectrophotometers also measure color, but with greater specificity. The visual appearance of foods is important to customers, so both instruments are very valuable in evaluating the QA process in measuring the color of test batches versus control specifications. If a sample batch falls outside of the tolerances for the color standard specified in the control sample, the batch will be rejected or flagged for further evaluation.

- Specific gravity is a measure of density, or weight per unit of volume. Since each ingredient in a recipe has a given density, the specific gravity of any test batch should match that of specific gravity of the control recipe. If the specific gravity in a test batch is off, it may indicate too high of a concentration of a particular ingredient, in which case it would be rejected, or flagged for further evaluation. Specific gravity can easily be measured using a hydrometer.

We strive to achieve the very highest levels of food safety and quality assurance. We believe our extensive scope of QA services translates into more consistent, and safer, food products for our customer base.