Inpipe Sweden AB

- Home

- Companies

- Inpipe Sweden AB

- Services

- Inpipe - Ultraviolet light for curing

Inpipe - Ultraviolet light for curing

FromInpipe Sweden AB

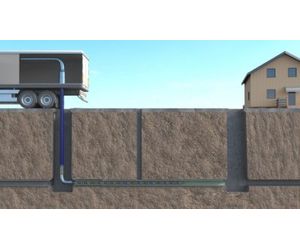

All Inpipe CIPP liners is cured by UV-light.

Curing with UV light is quick, safe and environmentally friendly. When the UV-light hits the polyester, a chemical reaction takes place that makes the polyester harden. This is robust, quick and effective as the UV cured liner is less sensitive to for example temperature variations when curing.

With UV cured liners, you avoid using energy to produce hot water/steam that then has to heat up the entire wall thickness of the liner to a certain temperature and for a certain time for it to be properly cured.

There is also reaserch and reports point towards the fact that UV-cured liners releases less amount of harmful chemicals during the curing phase. This can be important for the health of your workers but also important for organisms in the environment.Most popular related searches

UV curing

process water

CIPP liner

ultraviolet lamp

process water chemical

ultraviolet water

water containment

chemical containment

water process chemical

produced water

The only energy that is used during UV light curing is the electricity that lights the UV lamps, which is effective in comparison to first heating a large quantity of water.

With UV hardening you avoid dealing with steam and process water that may contain harmful chemicals which should not be released into the environment or inhaled.

- The method is quick. You can cure up to approx. 90 m of liner per hour.

- Low energy consumption keeps emissions to a minimal level.

- No process water or steam that can contain harmful chemicals is created.

- The equipment requires little space on the worksite.