- Home

- Companies

- Inpipe Sweden AB

- Services

- Inversion of CIPP-liners

Inversion of CIPP-liners

Think about what you do to invert the sleeve of a sweater that’s inside out.

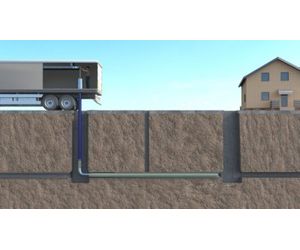

Our method and our liners work in a similar way. They are manufactured inside out and are inverted during the installation process as they are pressed into the pipe. This is done using compressed air.

The majority of the inversion operation takes place from inside your installation vehicle.

When the glass fibre reinforced liner is inverted in to place in the pipe, the liner is pressed tightly against the existing pipe by air pressure.

After this the UV light train is pulled into the pipe directly from the vehicle using our ingenious system and the hardening process can begin.

All of our liners are hardened with UV light.

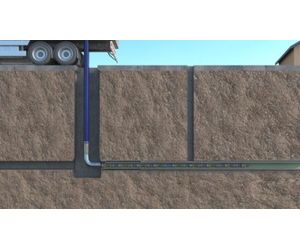

The entire installation process takes place whit the air pressure maintained to ensure the best possible fit and reduce the risk of errors and problems.

The technique gives you a very close fit between liner and existing pipe. Any water remaining in hollows in the pipe is pressed out during the installation. This helps ensure that there is no risk of the pipe form changing, and you retain the cross-sectional area of the pipe.

The gap between the existing pipe and the liner is minimal: <0.1% of the diameter.

- Adapted for liners up to Ø500 mm and uop to about 160 m long.

- The method is effective, the installation is quick, saves resources and is environmentally friendly.

- Gives a minimal gap between the existing pipe and the liner.

- Safe work environment as very little work has to be done down in manholes.

- Because the liner is inflated as it is installed, remaining water in hollows in the pipe is pressed out. This leads to a very good fit in the existing pipe with a minimal gap.

- Not suitable for liners over Ø500 mm in diameter or sections in excess of 160 m long.

- Requires specialised installation equipment.