Harsco Metals & Minerals

- Home

- Companies

- Harsco Metals & Minerals

- Services

- Slag By-Product Resource Recovery ...

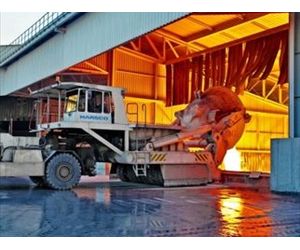

Slag By-Product Resource Recovery Solutions

Harsco provides a range of solutions for recycling slag. We process Blast Furnace slag, Converter slag and Ladle slag, to meet the specific chemical, mechanical and physical properties required of the final recycled product. We also comply with local environmental regulations.

Most popular related searches

resource recovery system

metal recovery process

metal recovery

resource recovery

environmental footprint

aggregate product

raw materials recycling

environmental regulations

scrap recycling

product environmental footprint

Our Slag Services include:

- Slag Transportation, Tipping, Digging and Weathering

- Metal recovery, Upgrading recovered metallics

- Marketing and Sale of residual slag product in local markets for a variety of applications

The features of recovering slag by-products are:

- Quality assurance throughout the metal recovery process, via sample testing of the metallic stream and the residual slag stream.

- Through our global R&D network, Harsco have developed entirely new markets for by-products in end use industries, even for stainless steel slag.

Our advantages are:

- Recovery of metallic units is optimised, and the scrap product is recycled into steelmaking, reducing raw material costs in steel production.

- The steelmaker also benefits by avoiding the cost of landfill for slag

- The community benefits, too. Slag is a man-made mineral, therefore its use as an aggregate in place of a natural aggregate product avoids the environmental footprint from quarrying.

Our Slag Services include:

- Slag Transportation, Tipping, Digging and Weathering

- Metal recovery, Upgrading recovered metallics

- Marketing of residual slag products in local markets for a variety of applications

Quality assurance throughout the metal recovery process, via sample testing of the metallic stream and the residual slag stream.

Through our global R&D network, Harsco have developed entirely new markets for by-products in end use industries, even for stainless steel slag.

Our advantages:

- Recovery of metallic units is optimised, and the scrap product is recycled into steelmaking, reducing raw material costs in steel production.

- The steelmaker also benefits by avoiding the cost of landfill for slag

- The community benefits, too. Slag is a man-made mineral, therefore its use as an aggregate avoids the environmental footprint from quarrying natural aggregates.