- Home

- Companies

- Hilliard Emission Controls, Inc. / ...

- Services

- Tank Degassing Service

Tank Degassing Service

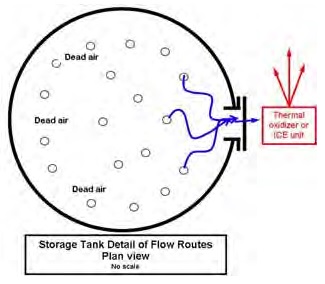

Channeling is detrimental to effective vapor control. Channeling of the vapor inside of tanks during degassing is a real problem1. Degassing is ineffective and time consuming if the vapors are not mixed or stirred. It is unreasonable to believe that effective vapor control can be achieved without mixing.

Every combustion system pulls in outside air through the vents on the roof or the leg openings and around the roof seal. The replacement air continues on the path of least resistance to the exit port. The plan view diagram on the left shows channeling on a floating roof tank.

The replacement air can come from the perimeter seal, open nozzles, openings around roof legs, gauge hatches and even the vacuum relief valve. This replacement air enters the tank at low flow rates and channels through the mass of hydrocarbon vapors. Channeling allows the majority of vapors we call ‘dead air’ or ‘stagnant vapor’ to remain in the tank. The dead air is not tested and not controlled efficiently if it is controlled at all.

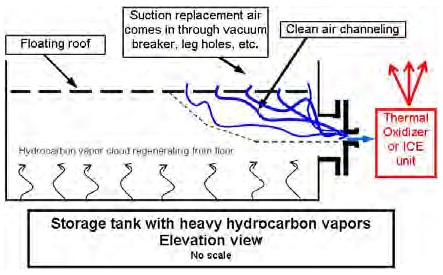

Heavy hydrocarbon clouds cause big problems. Hydrocarbon clouds are the result of cargo evaporation from the floor.

Hydrocarbon vapors are heavier than air and they lay on the floor of the tank like a cloud. This concentrated VOC cloud grows from the evaporation (or flashing) of cargo inside the tank. The condition is called regeneration.

When using a combustion device and pulling from one outlet, all the heavy vapors below the exit port remain largely undisturbed. The VOC is not drawn to the control device in a timely fashion.

In addition, concentration samples taken at the control device inlet are not representative of the over-all tank vapor.

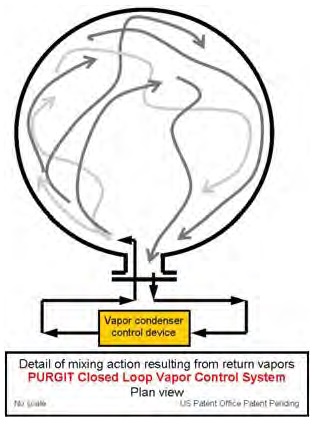

The PURGIT system solves the problem of channeling. PURGIT is the only degassing contractor in the country that operates with a return stream to the tank. That mixes the vapors in the tank eliminating dead air and stagnant vapors. The tank owners gets an efficient and thorough degassing job.

The extra movement inside the tank encourages the cargo to evaporate from the floor and that shortens the time it takes to degas the tank.

Another advantage is that the mixing provides an accurate cross section of the vapor when testing at the control device. Without thorough mixing, it is not possible to get a representative sample of the tank vapor to determine whether state and facility specifications are met.

Another important benefit of our technique is the elimination of greenhouse gas production during tank degassing. There is no combustion in our condensers and the condenser system becomes an extension of the storage tank. That reduces emissions.

Another advantage is that the mixing provides an accurate cross section of the vapor when testing at the control device. Without thorough mixing, it is not possible to get a representative sample of the tank vapor to determine whether state and facility specifications are met.

Another important benefit of our technique is the elimination of greenhouse gas production during tank degassing. There is no combustion in our condensers and the condenser system becomes an extension of the storage tank. That reduces emissions.