- Home

- Companies

- ASI Group Ltd.

- Services

- Tunnel & Pipeline Inspections Services

Tunnel & Pipeline Inspections Services

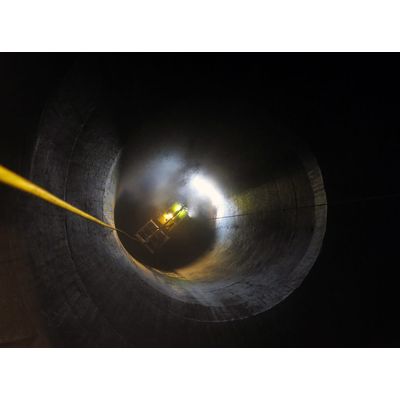

ASI has pioneered techniques and developed equipment specifically designed for underwater tunnel and pipeline inspections. Our advanced robotic vehicles are controlled from the surface and data from the vehicle sensors are displayed in real-time and recorded for future review. They use the latest navigation, sonar and video imaging equipment to provide critical data for condition assessment programs. Knowing the true condition of the assets supports the development of maintenance and repair schedules for operational and financial optimization.

- generate a georeferenced 3D model of the tunnel,

- determine areas of leakage (ingress or egress),

- provide extended live monitoring of conditions when construction activities may negatively impact tunnel or pipeline integrity,

- acquire high resolution sonar or video imagery of specific areas of features of interest.

These unique capabilities place ASI as the world leader for long tunnel inspection work.

ASI’s comprehensive fleet of ROVs supports the inspection of tunnels and pipelines in the flooded state saving time, money and avoiding the risks associated with de-watering these structures.

Inspection of tunnels and pipelines can present challenges. Tunnels and pipelines are often hidden from sight, have limited access and can be several kilometers (miles) long. De-watering tunnels and pipelines for walk-through inspection is not always possible and when attempted, can be dangerous and costly. In some cases, the inspection of the tunnel or pipeline cannot be accomplished as some facilities were not built with the intent of ever isolating or dewatering them. Leaving a tunnel or pipeline in a watered state during inspection eliminates the time required to safely dewater and eliminate water waste.

In order to provide accurate dimensional information of a tunnel, ASI operates a variety of sonar systems that use sound to measure distances in the underwater environment. Since the ability of the sonar to measure distances in not impacted by visibility, tunnels in excess of 20 meters nominal diameter have been surveyed by ASI using proprietary sonar systems configured to measure 360 degrees instantaneously.

Some of these systems provide over 1,500 points at each cross-sectional measurement. If necessary, they can do so at up to 50 times per second. The instantaneous profiles are displayed to the operators and are processed into a 3D point cloud model of the tunnel. All of this is done in real-time as the pilot flies the vehicle along the tunnel. 3D points with XYZ value provide immediate information to the owner on the tunnel condition. Further processing provides a model that is completely geo-referenced to the owner’s coordinate system. This makes ASI’s data easily integrated into a GIS system of the owner’s assets.

- ROV technology allows inspection, detailed imagery and data collection while pipelines and tunnels remain flooded.

- Tunnel inspection technology provides current-state and future-state predictions of infrastructure integrity.

- Reduce down-time, save money and schedule upgrades through inspection protocol and planned investment.

- Fast mobilization of a full team of expert marine engineers, commercial divers, ROV pilots and fleet of vessels.

- World-wide experience across industries including hydroelectric, nuclear, archaeological, marine construction.

- Versatility and state-of-the-art equipment to deal with the most complex technical assignments in the world.

- Custom spot-repair solutions and equipment adaptation as needed to perform assignments.

- Obtain high-accuracy data collection in flooded conditions.

- Collection of interactive volume and surface analysis data used for comprehensive studies or investigations.

- Customized solutions for leak detection and repair.