- Home

- Companies

- ASI Group Ltd.

- Services

- Underwater Dam Inspection Services

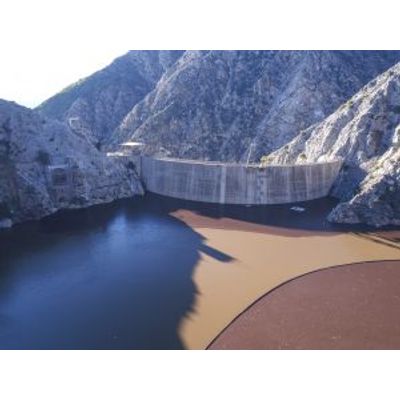

Underwater Dam Inspection Services

ASI provides pertinent information for dam safety assessments. Regular inspections can prevent dam failures. Remote technology can help. Inspection and maintenance are critical to the performance and longevity of underwater infrastructures. Measurable data, images and videos can be collected using remote technologies for underwater dam inspections, condition assessments and regulated inspection reports. ASI has gained international recognition for researching and developing remote techniques for underwater dam inspection, repair and maintenance. With limited to no impact on normal plant operating conditions, ASI has developed methodologies that use sonar systems to capture and present pertinent data for asset management. Our team of remotely operated vehicle (ROV) pilots, technicians, engineers and certified hydrographers are well-versed in underwater data collection and have gained vast experience working at numerous dam sites across the globe.

ASI’s inspection data can identify offsets, misalignments of concrete slabs, leaks, silt accumulation, and spalling, among others. This crucial information helps identify conditions that may adversely affect the safety and functionality of a dam and associated underwater structure. In addition, comparative analysis of repeat inspection data can help identify trends in features of interest, assisting in the development of maintenance and repair programs.

- Bridges

- Piers

- Gates

- Gate slots

- Sluice gates

- Penstocks

- Draft tubes

- Spillways

- Tailraces

- Training walls

- Powerhouses

- Water towers, and

- Reservoirs

Through use of the most advanced equipment and techniques, ASI provides a comprehensive and detailed representation of existing conditions below the water’s surface. Data collection is consistently completed in a safe and efficient manner, removing the dangers associated with personnel in the water and minimizing a plant’s operational downtime. Additionally, ASI’s data collection is always performed to high standards. The comprehensive reports provide a solid baseline for future dam inspections comparisons.

Advanced 2D and 3D sonar systems provide detailed data for understanding and quantifying underwater conditions both safely and efficiently. This supports true underwater condition assessments so that maintenance activities can be planned for instead of reacted to, introducing further cost savings.