- Home

- Companies

- KLINGELNBERG Group

- Software

- KLINGELNBERG - Cylindrical Gear ...

KLINGELNBERG - Cylindrical Gear Software

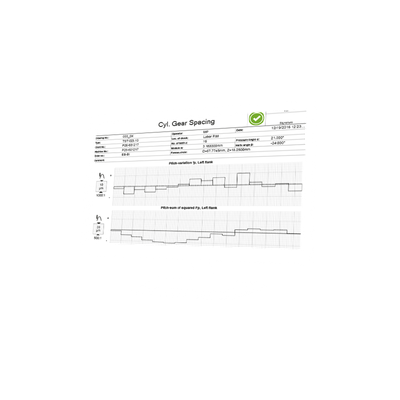

Klingelnberg's cylindrical gear software is a pivotal tool within gear measuring technology, establishing itself as an industry standard across the globe with thousands of installations. Its role is integral to measuring center operations, providing accurate, timely measurements with robust software support. By accommodating a diverse array of evaluations, the software adheres to both national and international standards and tolerance fields. It is adept at assessing corrected gear teeth, including crowned, conical, and bevel gears, as well as executing advanced measurements for twist, root, and tip relief, along with topography assessments. The system also features workpiece axis determination, rolling path calculations based on mating gear data, and secure measurement curve archiving. The software serves as the backbone for the Closed Loop system, allowing for seamless integration of optional modules tailored to complex measuring tasks, such as interrupted tooth traces and segment gearing analysis, thereby enhancing measurement precision and functionality.

In addition to the general qualities of precision measuring centers such as short measuring times, high measuring accuracy and sturdy design, other advantages are extremely dependent upon the type of software that is available. Not only does modern software application have to carry out the required measurements completely and in compliance with the standards, it must also meet additional criteria.

Klingelnberg's cylindrical gear software is the most widely used software in gear measuring technology, and is recognized as the international standard in the industry. Evidence of this is the fact that several thousand installations are already in use around the globe. At the same time, the software represents the basis of the unique Closed Loop system – a truly unique selling proposition in the industry.

The cylindrical gear software makes it possible to carry out a wide range of evaluations in accordance with numerous national and international standards and tolerance fields (templates). As well as corrected gear teeth (such as crowned, conical, beveled and beveloid gears), the software is also capable of measuring and evaluating twist, root and tip relief, and topography. The standard cylindrical gear software package includes workpiece axis determination, rolling path calculation in accordance with mating gear data, the storage of measurement curves for archiving, and password protection for a wide range of input levels.

At the end of the day, Klingelnberg measures up to any job: Numerous special modules can be optionally added by customer request. These include the testing of interrupted tooth traces or segment gearing, for example, position measurement and angular position measurement of multiple gear teeth, and grinding burn testing of cylindrical gear tooth flanks, to name but a few.

- Internationally recognized industry standard and the most widely used software in gear measuring technology at the same time

- Several thousand installations are already in use around the globe

- Basic software for Klingelnberg’s unique closed loop system

- Measurement and evaluation of crowned, conical, beveled and beveloid gears, root and tip relief, and topography

- Numerous special modules available by customer request