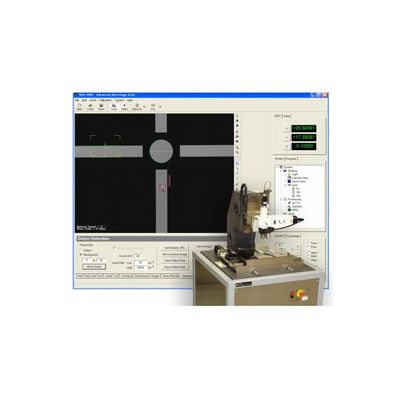

NGS - Automated Microscope for CD, Overlay, and Defect Detection System

Automatic Defect Detection & Classification

Automated Die Inspection

Precision Dimensional Metrology

Critical Dimension (CD) and Overlay Metrology Automatic and Manual Operation

- VCSEL CD Measurement

- Surface & Edge Defect Detection

- Texture Defect Detection (e.g. stains, etc.)

- Missing or Deformed Object Detection

- Extensive Defect Review Capability

- Graphic Maps & Image Archival

- CAD file import

The NGS Series defect detection and metrology systems are designed for applications where automated optical defect detection and precision dimensional measurements on wafers and other parts are required. They are well suited for dual use as production tools or as versatile process development systems. These systems offer a choice of high end microscope components (Olympus/Nikon/Leica), BF/ DF/ DIC illumination, and linear motor staging with 0.02 micron scales. There are several configurations available depending on your requirements. These include:a 200mm platform, a 300mm platform and a robotic platform for automated wafer and part handling.