- Home

- Companies

- Optrak Distribution Software Ltd

- Software

- Operational Planning and Optimisation

Operational Planning and Optimisation

Optrak is a Vehicle Routing and Scheduling system that can save you money, reduce your planning time and improve your customer service. Look at how we helped Fuchs Lubricants improve all their KPIs.

Better Routing

Delivering the same number of goods with fewer vehicles and less mileage will save you money. It will reduce your carbon footprint. Using Optrak’s optimiser, our customers typically achieve a saving of between 5% and 15% on direct transport costs, depending on the complexity of the problem and the existing planning setup.

Generally, the more complex your planning problem, the bigger the percentage potential savings you can obtain. Look at what Brakes achieved at their Egham depot.

Loading the vehicle

Unless you deliver full loads or full pallets, working out if the vehicle is full is often quite difficult. A common problem is having a mixture of pallets and roll-cages. Pallets fit neatly 2 across, roll-cages typically 3 across. But mixing the two rarely gives a tidy solution.

Optrak has integrated vehicle loading capability – loads are constructed as the routes are built, ensuring that loads are always possible. See Optrak Vehicle Loading for more information about how we ensure that vehicles can be properly filled.

Most operations use 3rd party carriers – parcels carriers, pallet networks or hired-in haulage. Different carriers have different rates. Your carriers will probably have overlapping service offerings and may cover the same areas at different costs. Which jobs should you do on your own fleet, which should you give to the carriers and which carriers should you use?

With Optrak you can build in the different carrier rates. For any order you can determine the cheapest carrier and its cost.

The optimiser can take carrier rates into account – prioritising orders onto your trips where you can do them more cost-effectively, or leaving them if the carrier rate is good.

Finally you can manually or automatically assign the orders to the chosen carrier and upload the results back to your order processing system or WMS so that they can be picked early and put aside for carrier collection.

Improving Customer Service

Do you compete on customer service? Most companies do. Optrak can help in a number of ways:

The right time

Optrak produces plans that meet your customer delivery windows. And if it is correctly calibrated and there are no unforeseen problems on the day, you will be able to meet those time windows.

Of course, unforeseen events do happen. But the better and more accurate the plan, the more likely you are to be able to sort something out. And if you use Optrak Realisation you will be able to control the situation through its integration with on-board computers.

The right vehicle

Have you had a failed delivery because a vehicle could not access the customer premises? Or the vehicle you sent had no tail-lift when one was needed?

Even though someone in your organisation knew about the problem?

With Optrak, you record your customers’ access restrictions and the system will always take them into account, eliminating this type of mistake and improving the customer’s confidence in your service.

Mulit-day Planning and Reducing lead time

If you have multi-day lead times you will know that it is all too easy to concentrate on tomorrow’s `must-go` orders and not to look further out to orders hat have 2 or 3 days remaining. Because Optrak allows you to deal with all the orders, you can easily bring deliveries forward to combine with must-go orders. This not only makes the routes more efficent, eliminating the need to visit the same area every day, but also reduces the lead time for many orders.

Fuchs found that the control that Optrak gives them, has enabled them to reduce the time between when am order is placed and delivery time.

Prioritisation

Sometimes there are simply too may orders to be delivered – for example due to absent drivers, vehicle breakdown or a sudden glut of orders.

Which do you deliver? How do you prioritise?

It is not only a matter of a customer ranking – you may have the trade off of one `silver` customer against 3 `bronze` ones, just because the silver customer is much further away.

In Optrak you can set priorities on the individual orders. It will take them into account. If the silver order has a priority of 100, but bronze orders are each 50, then 3 bronze orders, with a total priority of 150 will be preferred. Priorities can be set automatically on the basis of customer characteristics, or set manually on the day.

Improved Control

Manual planning is often done with a `pigeon hole` system or a whiteboard - the drivers are given a pile of delivery notes and left to get on with it. Even if you set the routes up in your WMS (Warehouse Management System), the drivers only get a list of stops with no timings. You don`t know where they are or what they are doing. If you invest in a vehicle tracking system it tells you where the vehicles are, and where they`ve been, but not where they should be or what they should do next. but with Optrak, each driver gets precise instructions on drop sequence and arrival times. And with Optrak Realisation, you can ensure that they are following the plan and can monitor their progress

Driver instructions

Optrak’s routes give expected arrival times at each customer. The Driver’s Manifest report – a printable report which you can give or send to the driver – clearly lays out the drop sequence, the expected time at each drop, and any time windows for the visit.

Driver start times

If you have customers with early delivery requirements, or if you want to beat the morning rush hour, your drivers must start early.

But how early?

If you are based in Luton and a driver has a 07:00 delivery in Watford, he will need to start around 06:15. But another driver, who’s first drop is 07:30 in Bromley will need to start much earlier.

Until you plan the trips you may not know which driver should start when. But they`ve often already gone home.

Optrak can automatically send an SMS message with start time to each driver to let them know when tomorrow’s round will start.

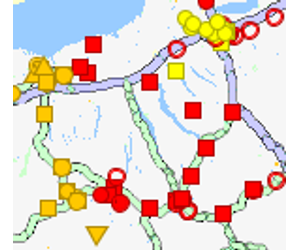

Your brain is very good at processing information presented as maps and diagrams - seeing groups and patterns that are hard to find from tabular data. A great strength of Optrak is the way it presents data visually so you can take full advantage of this capability. For example colouring orders by type, depot or whether they have been planned yet.

Simply by looking at problems on the map, our users are often able to make connections and see things that help them make decisions.

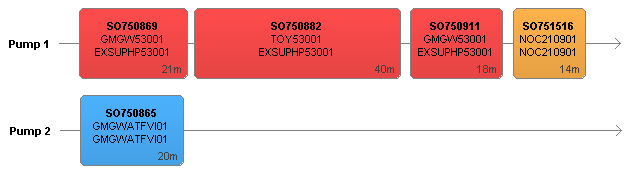

Maps are not the only way data can be displayed graphically. For bulk lubricant deliveries, the pump-off sequence for the different oil types is vitally important – to prevent contamination of pump and hose reel.

Optrak has been designed to allow you to see the information you need to fully understand the planning problem and solution, in the way that best suits your planning process.

The Process

The diagram below shows how Optrak is typically used to produce an operational plan.

The next stage is to run the optimiser.

The user reviews the results – possibly making changes to the trips using drag-and-drop or changing source data (for example, two orders, close to each other, may have completely different time-windows – changing a time-window could lead to a much more efficient route).

When the optimisation and editing are complete, the user then uploads the solution to the WMS or sales system. In the WMS it can be used to help picking in the warehouse.

Finally, reports are printed for use by drivers or other transport office staff.

Now you have the plan. With Optrak Realisation you can control, manage and report on the vehicles on the road, and you can collect and review your KPIs and other performance data.