Your competitive advantage begins with complete process control

Cost-Saving Alerts Process Automation Process Control Shot-To-Shot Data

- Know the moment a process changes

- Reduce machine downtime

- Lower waste and make good parts again fast

Prevent bad parts getting to customers from inaccurate variations.

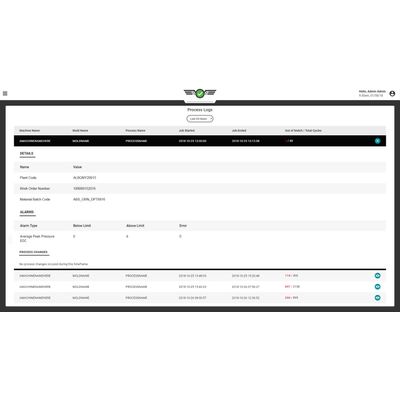

Know when a process was changed, why, and by whom to improve communication and accountability

Improve overall equipment effectiveness and reduce machine downtime

An advanced, easy-to-use interface that ensures the accuracy of your parts and the efficiency of your output

TOTAL PART AND PROCESS AUDIT RECORDS

Croate an audit trail so you can prove every shot that leaves your facility to reduce risk should a product fail.

REDUCED OR POTENTIALLY ZERO SCRAP

Address top industrial issues, such as dimensional and material variations and shipping out bad parts.

BUILT-IN INJECTION MOLDING EXPERTISE

See what is happening inside the mold to make data-driven decisions and ensure the highest part quality.

REDUCE MACHINE DOWNTIME

Immediately know when a process strays and why so you can start making good parts again fast.

REAL-TIME ADJUSTMENTS WITH REMOTE ACCESS

View how all of your machines are performing and troubleshoot efficiently from anywhere in the world.

REDUCED HUMAN ERROR WITH PROCESS AUTOMATION

Get consistent quality across machines and facilities around the world with minimal risk of human error with process automation.