- Home

- Companies

- KLINGELNBERG Group

- Software

- KLINGELNBERG - Roughness Measurement ...

KLINGELNBERG - Roughness Measurement Software with Roughness Measurement

KLINGELNBERG offers advanced precision measuring centers in their P-series, which are equipped with high-precision roughness measurement devices. These devices enable fully automated integration into gearing and coordinate measurements, allowing all measurement processes to be completed in one clamping. The precision CNC-controlled procedures ensure a reproducibility of 0.01 µm, making it suitable for measuring intricate structures on gear teeth as small as module 0.9. The innovative design of the miniature roughness probe maximizes contact with the gear surface, providing precise measurements even on barrel-finished teeth. The evaluation is presented in detailed reports containing graphs and the roughness parameters crucial for assessing gear quality. The software offers customized solutions tailored to various measurement needs, including angled probes for bevel gear measurements. It ensures high precision even in challenging shop-floor environments, contributing to improved manufacturing accuracy and efficiency.

THE SMART WAY OF MEASURING

All Klingelnberg precision measuring centers in the P-series can be also equipped with a high-precision roughness measurement device. This roughness measurement can be integrated fully automatically into both gearing measurement and coordinate measurement, meaning that all measurements can be carried out in a single clamping.

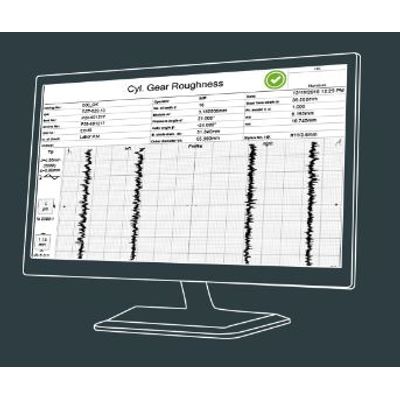

Reproducibility of 0.01 µm is achieved with the precision CNC-controlled measuring procedures. The innovative miniature roughness probe also makes it possible to carry out fully automatic measurement of gear teeth as small as module 0.9. This is possible thanks to a specially developed design that provides contact with the largest possible area of the gearing surface. Even the most intricate structures on barrel-finished gear teeth can be measured and evaluated with the utmost precision. The measurements are then evaluated in a clear, readable report which accurately shows the roughness measurement graphs and the roughness and contact ratio parameters. High-precision measurement is guaranteed, even in the shop-floor environment!

Our customers obtain made-to-measure solutions every time with Klingelnberg’s roughness measurement software: For bevel gear measurements, for example, angled probes are available for ring gears as well as the standard straight design for pinions.

- Fully automatic roughness measurement of gear teeth as small as module 0.9 mm, as well as shafts and plane surfaces

- Robust, reproducible measuring results, even on extremely smooth (e.g., barrel-finished) surfaces

- Evaluation of roughness parameters in accordance with DIN EN ISO 4287 (Ra, Rz, Rt, Rmax)

- Evaluation of contact ratio parameters in accordance with DIN EN ISO 13565-2 (Rk, Rpk, Rvk, MR1, MR2)

- Easy handling through integration into the normal measuring process

- Precise measurement, even in the shop-floor environment