- Home

- Companies

- Flow Science, Inc.

- Software

- Flow Science - Version FLOW-3D CAST - ...

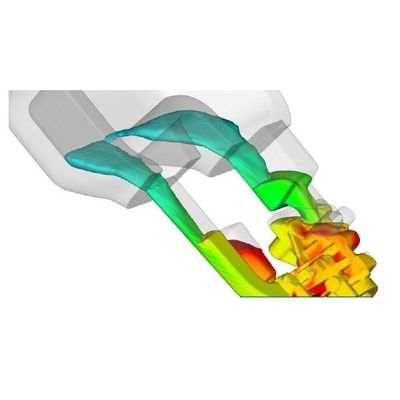

Flow Science - Version FLOW-3D CAST -Tilt Pour Casting Workspace

In this FLOW-3D CAST simulation of an 8-cavity tilt pour casting, A356 aluminum is poured at 738 C by rotating the mold from a horizontal orientation to a vertical orientation over 18 seconds. The H13 steel mold is thermally prepared by simulating 5 cycles of fill/solidify/spray cooling using FLOW-3D CAST’s thermal die cycling model.

The Tilt Pour Casting Workspace is an intuitive modeling environment designed to help engineers successfully model tilt pour casting applications with FLOW-3D CAST. The workspace includes process-specific die and material types, where rotational motions are easily defined in order to match exact machine capabilities. Venting and backpressure are included in the fill analysis for a complete analysis of air entrapment defects, while thermal die cycling and state-of-the-art solidification models are seamlessly connected to the fill through the workspace’s sub-process architecture. The Tilt Pour Casting Workspace provides a complete and accurate solution for all aspects of the simulation in a simple yet versatile modeling environment.

PROCESSES MODELED

- Tilt pour

- Reverse tilt pour

FLEXIBLE MESHING

- FAVOR™ simple mesh generation tool

- Multi-block meshing

- Conforming meshing

DIE THERMAL MANAGMENT

- Thermal die cycling

- Heat saturation

- Full heat transfer modeling

ADVANCED SOLIDIFICATION

- Porosity prediction

- Shrinkage

- Hot spots identification

- Thermal modulus

- Mechanical property prediction

SAND CORES

- Core gas evolution

- Material definitions for core properties

MOLD MOTION CONTROL

- Six axes of rotation

- Tabular input for rotational velocities

DEFECT PREDICTION

- Macro and micro porosity

- Gas porosity

- Early solidification

- Oxide formation

- Surface defect analysis

DYNAMIC SIMULATION CONTROL

- Event probe-based triggers for motion control

COMPLETE ANALYSIS PACKAGE

- Animations with multi-viewports - 3D, 2D, history plots, volume rendering

- Porosity analysis tool

- Side-by-side simulation results comparison

- Sensors for measuring melt temperature, solid fraction

- Particle tracers

- Batch post-processing

- Report generation