- Home

- Companies

- CIC Photonics

- Software

- Version SPGAS - Specialty Gas Analysis ...

Version SPGAS -Specialty Gas Analysis Control Software System

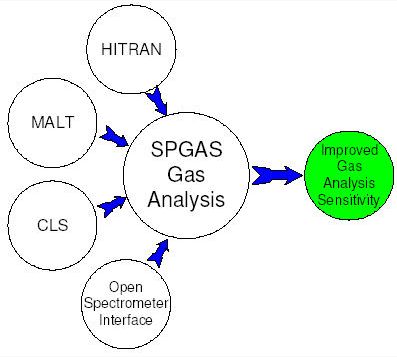

To provide for a Turnkey Industrial Integrated Real-Time Gas Analysis System. To be client tailorable. To offer a modular design. To be hardware independent. To utilize state of the art analysis tools.

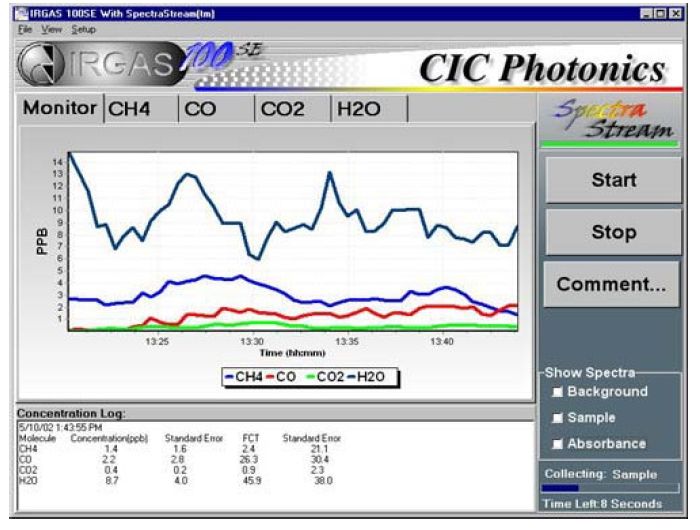

SPGAS is a user-friendly, turnkey FTIR software package designed specifically for the analysis of gaseous constituents. While providing all of the control features of a standard FTIR software package for Bomem spectrometers, SPGAS also provides the ability for 24/7/365 operation of the IRGAS analysis package. SPGAS is designed to save spectral files from each day of operations within it’s own automatically created directory structure for ease of retrieval. It is designed to save these spectral files in a format that allows spectral interchange with other FTIR software programs. The software automatically generates and maintains running logs of results that can be graphically displayed in real time and re-generated via an easily accomplished export to a spreadsheet program like Microsoft Excel.

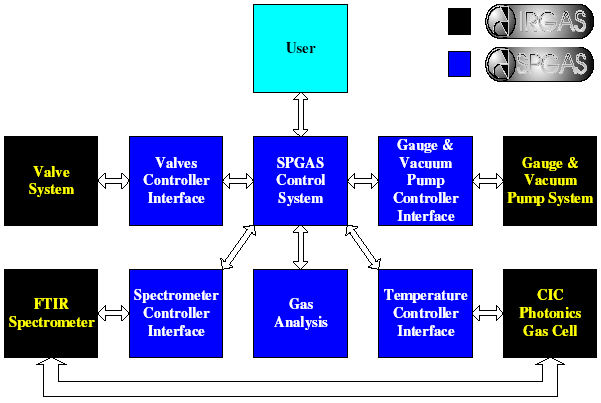

SPGAS does more than run ABB Bomem spectrometers. As seen in the Figure below, properly configured, the SPGAS software package can automatically run external hardware in support of the FTIR spectrometer. This allows SPGAS to collect temperature and pressure data and modify the calibration information to compensate for small changes in the gas cell temperature or pressure. SPGAS can also control valves and external events and track which gas stream is being sampled at any point in time.

The valve information is stored in the generated log file. Furthermore, SPGAS can provide external event control for such things as analog-out reporting, valve events, and alarm control.

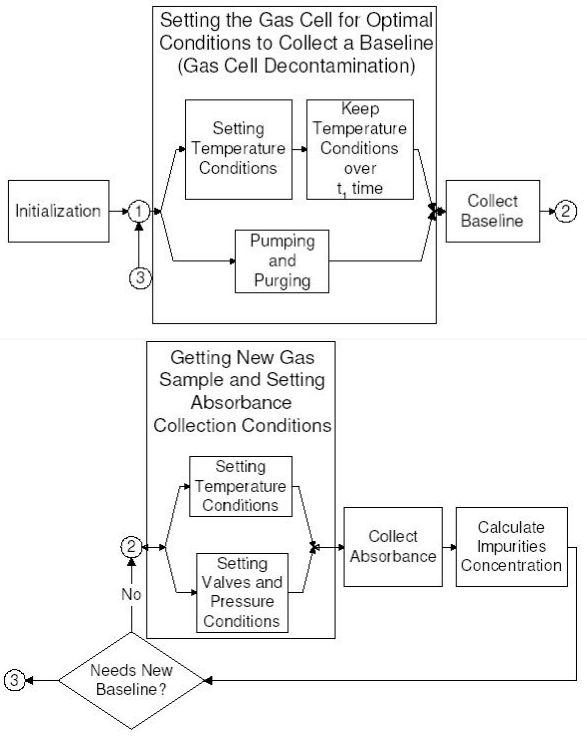

One of the more interesting aspects of SPGAS is the use of automated mirrors that can be installed in CICP’s gas cells. With automated mirrors, SPGAS software can run the SpectraStream Module (U.S. Patent # 6,748,334) to rapidly collect background spectra and sample spectra one after the other. This allows the SPGAS software to update the background spectra to compensate for small changes in the background levels of such constituents as CO2 and moisture. This provides a more accurate baseline subtraction routine which results in more accurate spectral modeling and more accurate results. The other advantage of running SpectraStream is the ability to identify even small changes in the sample spectra over the background spectra and report these changes to the operator.

A further advantage of automated mirrors is the ability to collect background spectra without having to clear the gas cell. This allows the gas cell to remain in operation continuously without having to be purged in order to collect an in-cell background spectra. This reduces the complexity of the system by eliminating the purge gas and the valves required to control the purge gas. It also allows the IRGAS system to operate in a remote location and in a completely automated manner without user intervention.

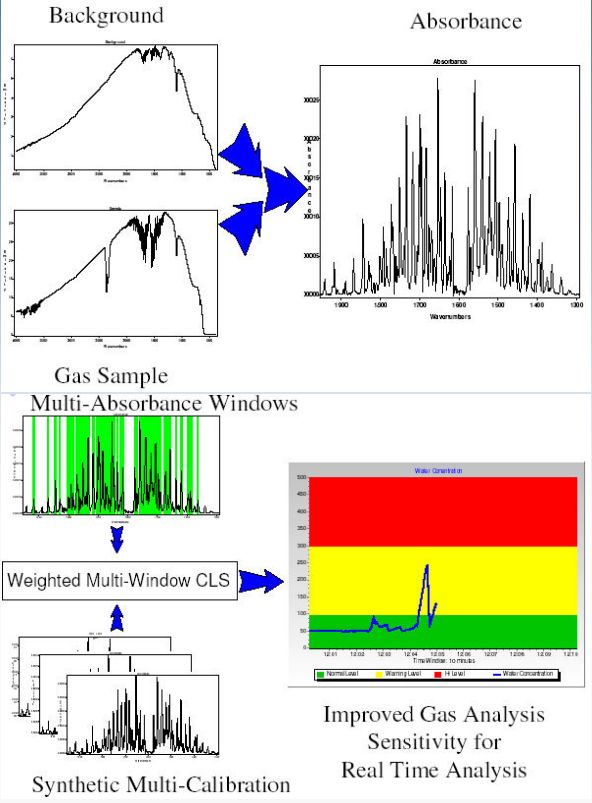

The SPGAS software package can be calibrated in a number of manners. For some gases, the HITRAN data base can be used as a synthetic calibration prior to shipping the system to the customer site. A partial list of HITRAN gases can be found in Table 1 below. For non-HITRAN gases, CIC Photonics will pre-calibrate the system for those gases requested for a small fee. For the user that has access to calibrated levels of those gases, CICP’s Qmax software provides an easy and efficient means of calibrating the system. Using Qmax, the end-user can take a collected spectra at a known concentration and quickly identify the appropriate spectral bands for use in the calibration. Having set up the calibration, the user can then collect multiple levels of calibration spectra and append them to the calibration file for that particular gaseous species. The user repeats the process for whatever number of gases desired. These calibration files are then combined in a single unique calibration data set that can be used for future analysis.

- Gas calibration based upon fundamental HITRAN data

- Weighted Multi-window CLS data analysis

- Infinite calibration data sets available

- 32 bits Architecture base on industrial standard Operating System (Win NT) Hardware Operation (1/2)

MALT

- Calculates spectra for single homogeneous path or for multiple layers

- Includes instrumental parameters into the calculations so the calculated spectra match the line shape, resolution and wavelength shift of the measure spectra.

- Uses HITRAN molecular spectroscopy databases

HITRAN/MALT vs. Actual Calibration

- Advantages

- Calibration data free of noise

- Best match to the measured spectrum according to the least-squares criteria

- Operational costs reduction

- Non time consuming calibrations

- Precision at least as good as that of traditional methods ( £ 3%)1

- Disadvantages

- Provide analysis only over gases included in the HITRAN database

- System requires regeneration of calibration data if spectrometer or gas cell change