- Home

- Companies

- Oizom Instruments Pvt. Ltd.

- Applications

- Data-Driven Process Control for ...

Data-Driven Process Control for Environmental Automation - Environmental

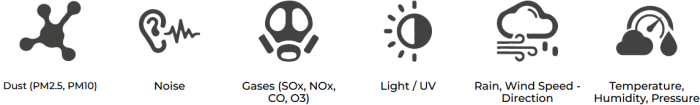

By monitoring various air-quality parameters like Dust, Gases, and Noise, the data is useful to take relevant environmental actions. To mitigate pollutants, various environmental-control equipment are available. By regulating such equipment and the manufacturing processes, efficient environmental management is possible. Such Environmental Automation leading to effective industrial process control can optimize processes to achieve goals like sound attenuation both inside and outside, dust removal, machine hall ventilation, and wet end process ventilation of an Industry.

By implementing various industrial process control solutions using AQBot, better workplace environmental management is possible. Such solutions optimize processes which may result in better energy efficiency as well as the quality of the goods manufactured in the industry.