- Home

- Companies

- Advanced Cyclone Systems, S. A. (ACS)

- Applications

- Emission control solutions for clinker ...

Emission control solutions for clinker cooler and pre-heater dedusting sector - Air and Climate

The control of clinker fines emissions after the heat exchanger, placed downstream of the clinker cooler, is usually a problem for cement plant managers. The process is characterized by high material abrasiveness, high loads and variable flow rate in normal and maximum conditions.

The usual dedusting arrangement includes a bag filter as a final stage deduster, which is typically associated with high maintenance costs and downtime in production due to frequent replacements of filter elements.

Reducing fine particulates from the exhaust stream of the pre-heater tower is also an objective in order to purify the air used for energy recovery, such as heating a petroleum coke or coal mill, thereby increasing the value of the grinded product. A high efficiency cyclone system is often used for this purpose.

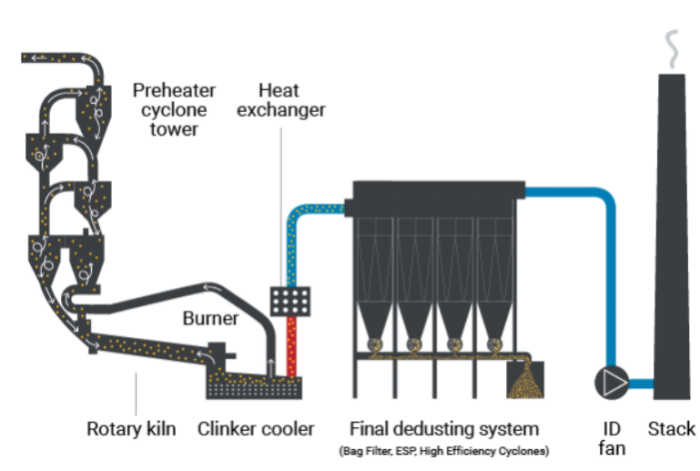

Clinker Cooler and Pre-Heater Dedusting | General Arrangement

The general arrangement of a cement plant includes two main exhaust gas streams: the clinker coolerand the pre-heater tower.

Clinker cooler:A bag filter is typically the final stage deduster downstream of a heat exchanger.

The Median Volume Diameter (MVD) of the particles coming from the exhaust gases from the clinker cooler is relatively coarse, ranging from 100µm to 150µm.

Pre-heater tower:A bag filter is usually the final stage deduster. High efficiency cyclones are used upstream to purify the exhaust stream used for energy recovery purposes in applications such as the grinding of coal or pet coke.

The Median Volume Diameter (MVD) of the particles coming from the pre-heater is typically very small, ranging from 2.4µm to 3µm.