- Home

- Companies

- Hiden Analytical Ltd.

- Articles

- Key Applications & Benefits of ...

Key Applications & Benefits of SIMS-Based End Point Detectors

Advanced semiconductor manufacturing necessitates control at every stage of the fabrication process, with etch processes being among the most critical to perform with precision. Even a microscopic deviation at a material interface can impact device performance, yield, and long-term reliability. Secondary Ion Mass Spectrometry (SIMS)-based end point detection has emerged as a dependable way to determine exactly when an etch process should stop, helping engineers maintain tight process windows and safeguard device integrity.

SIMS is a surface analysis technique that detects secondary ions ejected from a material as it is bombarded by a focused ion beam. During semiconductor etching, these ions reveal the chemical makeup of the exposed surface in real time, providing a compositional profile of the layer being removed. Over the course of the etching process, the composition changes following the exposure of a new layer. By detecting these changes in the ion signal, a SIMS-based end point detector can determine the precise moment to halt the process. Featuring high sensitivity and depth resolution at the sub-nanometre scale, SIMS-based end point detection ensures accurate layer termination across a wide range of materials, including semiconductors, dielectrics, metals, and complex multi-layer stacks. These capabilities make SIMS-based end point detection essential for modern semiconductor processing.

Etch End Point Detection

A SIMS-based end point detector monitors variations in the signal intensities of secondary ions ejected from the target material during ion beam etching, signalling the exact moment each layer is reached. In III–V semiconductor fabrication, for example, it can confirm the precise GaAs/InGaAs interface, preventing over-etching into the next layer.

End Point Validation in Multi-Layer Stacks

For complex device structures, SIMS-based end point detectors can verify each interface with real-time accuracy. This is particularly important when a layer transition produces only a slight shift in the ion signal, making accurate detection essential for stopping the etch before it crosses into the next layer.

Yield Protection in High-Volume Manufacturing

Production environments, such as high-volume semiconductor fabs, can utilise SIMS-based end point detectors to ensure consistent layer termination wafer-to-wafer, reducing variability and preventing scrap due to over-etch or under-etch.

Process Development and Optimisation

In Research & Development (R&D), SIMS-based end point detectors enable engineers to fine-tune the primary ion beam’s energy, angle, and chemistry while monitoring how changes affect the endpoint signal. The result is faster recipe development and reduced wafer consumption.

There are many advantages to using SIMS-based end point detectors that span the full semiconductor workflow, supporting everything from early R&D to pilot lines and high-volume manufacturing. The key benefits of SIMS-based end point detectors include:

- High Sensitivity: Detects trace elements and subtle compositional changes for precise layer identification.

- Sub-Nanometre Depth Resolution: Ensures the process stops exactly where intended, preventing over-etching or under-etching.

- Real-Time Process Control: Provides immediate feedback so adjustments can be made during the run.

- Yield Protection: Reduces defects caused by process variation, improving overall manufacturing efficiency.

IMP-EPD

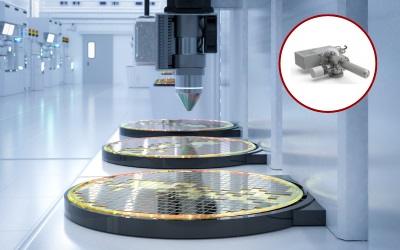

The IMP-EPD from Hiden Analytical is a robust, differentially pumped SIMS detector engineered for live endpoint detection in ion beam etching. It delivers sub-nanometre accuracy and maintains stable performance even under high-throughput manufacturing conditions. Integrated directly into etch systems, the IMP-EPD feeds endpoint data into process control loops, enabling precise layer termination without slowing production. Such a combination of accuracy, stability, and seamless implementation positions the IMP-EPD as a dependable tool for both R&D and high-volume manufacturing, establishing it as an asset in achieving tighter process windows and higher yields.

EP-Replayer

Hiden Analytical also offers the EP-Replayer, a software-driven tool designed to work alongside the IMP-EPD by allowing engineers to replay and reanalyse endpoint data during etch reruns. It establishes the detailed post-process examination of ion signal profiles, removing the need to rerun wafers purely for endpoint optimisation. With these abilities comes fast process optimisation, reduced material waste, and smoother recipe transfer between development to production.

In R&D / Process Development

- IMP-EPD: Provides real-time SIMs feedback, offering researchers a detailed view of layer removal sequences during etchings.

- IMP-EPD: Enables fine-tuning of the beam energy, angle, and chemistry and delivers immediate insight into endpoint effects.

- EP-Replayer: Allows for the replay and reanalysis of endpoint data from a single wafer run, refining detection algorithms without consuming additional wafers.

In Manufacturing / Production

- IMP-EPD: Delivers automatic, highly accurate endpoint detection to ensure product uniformity and maintain tight process windows.

- IMP-EPD: Protects yield by preventing over-etch damage and under-etch rework, reducing scrap and associated costs.

- EP-Replayer: Supports continuous recipe optimisation between production runs without taking tools offline, enabling faster production ramps.

- IMP-EPD and EP-Replayer: Detect early signs of process drift, enabling proactive corrections before large volumes are affected.

Meeting the demands of modern semiconductor manufacturing requires SIMS-based end point detectors that deliver precision and insight to maintain tight process control, protect yield, and accelerate the transition from development to high-volume production. Hiden Analytical’s IMP-EPD and EP-Replayer take these benefits further by combining robust, in-situ detection with advanced data analysis tools. Whether deployed in a research lab exploring next-generation semiconductors or on the production floor of a high-volume fab, they provide the accuracy, repeatability, and efficiency engineers need to achieve consistent results. To find out how the IMP-EPD and EP-Replayer could enhance your etch processes, contact Hiden Analytical today.