- Home

- Companies

- ABM Sensor Technology

- Articles

- Level Measurement 101: Importance, ...

Level Measurement 101: Importance, Types, & Sensor Selection

What is level measurement?

Level measurement is the process of measuring the level of a liquid or solid material inside a tank, silo, container or other vessel. Measurement is calculated from the distance between the liquid or solid material surface and a predetermined reference point, such as the top of a tank. Level measurement is typically expressed in feet or meters and can also be given as a percentage (i.e. 55% full). Level measurement can also be used to determine volume or mass.

READ THE FULL ARTICLE ON OUR BLOG HERE.

Why is level measurement important?

Accurate and reliable level measurement is essential for many process applications. Monitoring and controlling the level of liquids or solid materials in tanks or other vessels is critical for manufacturing process control and automation, inventory management, maintaining safety, ensuring efficient operations, optimizing production and much more.

Process control and optimization

Level measurement is essential for maintaining optimal process conditions by monitoring the level of liquids or solids in a vessel and relaying the information for control and optimization. Precise control ensures continuous production – no downtime, prevents overflows or shortages, and improves product quality and operational efficiency.

Inventory Management

Inventory is critical for continuous production, and level measurement plays a vital role in control and management by monitoring the level of liquid or solid material in storage tanks, silos or containers. Monitoring inventory levels enables manufacturing plants to plan production, optimize ordering, avoid stockouts or excess inventory, and minimize production downtime.

Safety

Level measurement helps ensure the safety of workers, process equipment and the environment. Overfilling or underfilling vessels can lead to unfavourable outcomes, including hazardous spills, equipment damage, and accidents. Monitoring level provides an early warning of high or low tank levels and enables operators to act quickly to minimize risk.

Quality control

For manufacturing processes with mixing, blending or reactions, level measurement is critical to help control ingredient ratio, concentration or dosage. Level measurement is also used for filling conditions and monitoring the shape or profile of finished products on conveyor systems for product consistency and quality standards.

What industries use level measurement?

Level measurement is used extensively across many industries for a variety of applications.

- Food and beverage

- Pharmaceutical

- Water and wastewater

- Chemical

- Oil and gas

- Mining

- Cement

- Construction

- Marine

- Environmental

- Agricultural

Types of Level Measurement

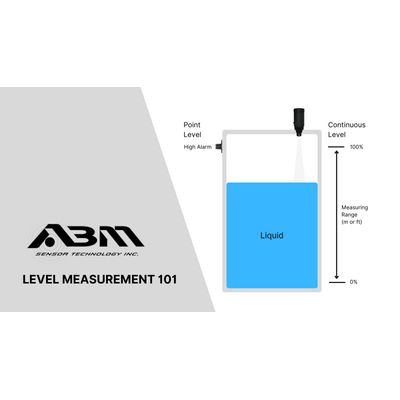

Continuous Level Measurement

Continuous level measurement provides real-time information on liquid or solid material levels in a vessel throughout the entire span. Continuous level measurement is commonly used for automation and integration with control systems and enables process optimization and improved efficiency.

Point Level Measurement

Point level measurement indicates whether the liquid or solid material has reached a certain level in a vessel. Point level measurement is commonly used for process control and triggering alarms.

Level Measurement Technologies

Many level measurement technologies are available, from simple to more advanced methods. Manual or mechanical methods such as floats, sight glasses, tape level or dip probes are simple, low-cost solutions without automation. In many cases, maintenance and manpower requirements are high. Advanced methods such as radar, ultrasonic, capacitance or laser technologies provide higher performance and automation capabilities for process control and require less manpower.

At ABM Sensor Technology, we specialize in ultrasonic and radar level measurement technologies.

Ultrasonic measurement

For ultrasonic measurement, the sensor transmits a pressure wave from a transducer that travels at the speed of sound to a target. The wave is reflected off the target and returns to the transmitter. The sensor receives the echo and calculates the distance between the sensor and the target using the time-of-flight principle.

Radar measurement

Radar sensors use electromagnetic waves for measurement focused by an antenna. The sensor emits electromagnetic pulses toward a target. The pulses reflect off the target and are received by the same antenna. Using the time-of-flight principle, the sensor calculates the distance between the sensor and the target.

Level Instrument Selection

When it comes to level measurement, there is no size fits all solution. Selecting the right level sensor for your application depends on material type and properties, vessel design, environment conditions (i.e. temperature, pressure, moisture, dust, and vapour), accuracy requirements, maintenance requirements, and budget. Working with a knowledgeable professional can offer guidance in selecting the right solution for your application.

ABM Sensor Technology has been a leading researcher, designer and manufacturer of ultrasonic and radar level sensor technologies for over 24 years.

For help with your level measurement application, contact us at +1 (705) 740-2010 or info@abmsensor.com.