- Home

- Companies

- Angst+Pfister

- Services

Angst+Pfister services

Engineering Capabilities

Solution Design & Development Services

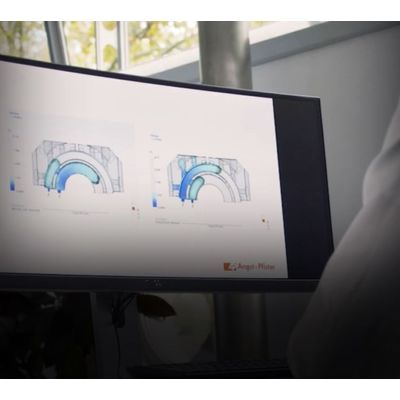

To design and develop the best solution for our customers, Angst+Pfister utilizes the latest CAD software tools, for life-time simulation and performance optimization. This approach ensures every product is meticulously designed down to the last detail before going into production. By integrating the Finite Element Method (FEA) analysis, we simulate performance and optimize designs for durability and efficiency. This approach enables precise material selection and design validation, significantly reducing the risk of failure in critical applications and ensuring the highest quality and reliability.

Solution Testing & Validation

Angst+Pfister specializes in advanced engineering solutions, offering a comprehensive range of services and products tailored to meet the strictest technical requirements. Their engineering capabilities encompass thorough solution testing and validation processes, using cutting-edge technologies to simulate real-world conditions and ensure product durability and performance. Techniques like multi-axis dynamic testing, high-frequency evaluations, and environmental simulations ensure products withstand demanding environments. Complementing these are surface treatments, such as sandblasting and zinc coating, enhancing bonding and corrosion resistance. Extensive testing methods, including force-deflection, bonding strength, ozone resistance, and creep testing, are employed to certify material reliability. Furthermore, ongoing investment in high-frequency testing accommodates the evolving demands of industries, such as electric vehicles, where vibration and noise are critical concerns. By employing Finite Element Analysis in product design and optimizing material formulations, Angst+Pfister delivers high-performance, customized solutions backed by a global network of technical support.

Angst+Pfister - Advanced Material and Compound Selection Solutions

Angst+Pfister pioneers material and compound selection as a central part of its engineering process, boasting a portfolio of over 2,500 distinct material formulations. These customized solutions cater to a diverse array of industries like Food and Beverage, Pharma and MedTech, Oil & Gas, and Automotive. With a strong foundation in research and development, Angst+Pfister utilizes sophisticated analytical tools alongside advanced production technology, from automated ingredient dosing to high-efficiency mixing machinery, to ensure the highest standards of durability, reliability, and precision. Their testing infrastructure employs comprehensive assessments, such as thermogravimetric analysis and calorimetric testing, ensuring that materials meet demanding industry standards, including chemical resistance and mechanical stress behavior. This approach positions Angst+Pfister as a leader in delivering industry-specific high-performance components by leveraging their meticulous, innovation-driven material science expertise.Solutions & Materials

Elastomeric Compounds for Sealing Solutions

Angst+Pfister offers advanced elastomeric compounds crucial for the development of next-generation sealing solutions. These formulations are designed meticulously to comply with industry standards while addressing specific transformation needs. The company provides a comprehensive range of standard and high-performance materials, including NBR, HNBR, EPDM, CR, as well as VMQ, FVMQ, FKM, and FFKM. These compounds are engineered to deliver excellence in diverse applications. Angst+Pfister emphasizes the creation of tailored solutions to meet individual application requirements or even the development of new high-performance parts to enhance product quality and safety. Their expertise and resources are essential for professionals seeking technical advice and customized solutions in various industries.O-Ring and Molded Parts Solutions

For over a century, O-rings have been the go-to choice for sealing applications across various industries. Angst+Pfister offers a meticulously curated assortment of high-performance elastomers tailored for standard applications, ensuring excellent sealing performance at a competitive price-performance ratio. Their extensive range of O-ring solutions is designed to meet the demands of diverse sectors, including food and beverage, medical, chemical, and more, providing unmatched reliability and durability in all applications. Angst+Pfister also excels in producing precision custom molded parts that are crafted to meet specific deployment purposes. By offering precise tailoring of molded seals to fit specific equipment designs, they ensure optimal functionality and maximum leak-tightness. Their advanced material portfolio includes compounds such as NBR and FFKM, engineered to perform exceptionally even in challenging conditions, enabling industries to stay ahead of the curve with evolving sealing needs.