- Home

- Companies

- Angst+Pfister

- Services

Angst+Pfister services

Engineering Capabilities

Solution Design & Development Services

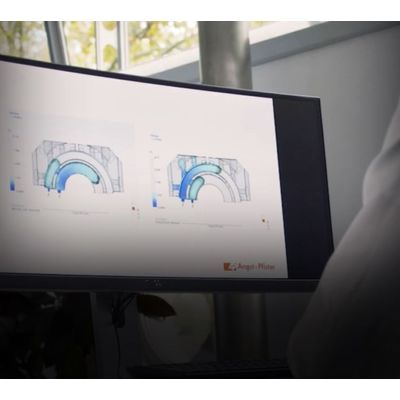

To design and develop the best solution for our customers, Angst+Pfister utilizes the latest CAD software tools, for life-time simulation and performance optimization. This approach ensures every product is meticulously designed down to the last detail before going into production. By integrating the Finite Element Method (FEA) analysis, we simulate performance and optimize designs for durability and efficiency. This approach enables precise material selection and design validation, significantly reducing the risk of failure in critical applications and ensuring the highest quality and reliability.

Solution Testing & Validation

Angst+Pfister specializes in advanced engineering solutions, offering a comprehensive range of services and products tailored to meet the strictest technical requirements. Their engineering capabilities encompass thorough solution testing and validation processes, using cutting-edge technologies to simulate real-world conditions and ensure product durability and performance. Techniques like multi-axis dynamic testing, high-frequency evaluations, and environmental simulations ensure products withstand demanding environments. Complementing these are surface treatments, such as sandblasting and zinc coating, enhancing bonding and corrosion resistance. Extensive testing methods, including force-deflection, bonding strength, ozone resistance, and creep testing, are employed to certify material reliability. Furthermore, ongoing investment in high-frequency testing accommodates the evolving demands of industries, such as electric vehicles, where vibration and noise are critical concerns. By employing Finite Element Analysis in product design and optimizing material formulations, Angst+Pfister delivers high-performance, customized solutions backed by a global network of technical support.