Cosme srl products

Flow Scheme

Cosme - Compact System for Pre-Treatment

NEW MODEL Compact System for pre-treatment of cesspool sewage series FCBD.

Coarse Screen

Cosme - Rotary Comb Screen

The arched screen is installed inside a reinforced concrete channel. Water flows through the grid perpendicularly to the bars.

Solid material present in the water deposits on the grid, while water, without the solids, continues to flow down in the channel.

Cleaning operation is done by polyethylene cleaning combs that, slowly rotating, pass through the openings, removing material from the grid and collecting it in a tank located in front of machine.

Medium and Fine Screening

Cosme - Vertical Chain Brush

Vertical chain brush filter is used to separate suspended solids from water in which they are present. Water to treat is conveyed inside a channel, where is located the machine. Filtering surface stops solids larger than filtering space and lets flow the filtered water. Cleaning of filtering surface is made by damper brushes installed on chain. These brushes have also the scope to transport solids removed from the filtering surface, till the point of discharge of machine. In this zone acts the scraper, which cleans the brush and unloads the screened material outside machine.

Screening Compaction

Cosme - Oleodynamic Compactor

Material to compact, which has high water content, enters into hopper and goes to the compression chamber. Here, passing from slots on bottom of chamber, material starts to drain the water in excess. Oleodynamic piston, guided by sliding blocks in brass, press the material towards the bottleneck located at the end of the compression chamber. Material, without ~ 25% of water, passes in the transport pipe (optional) to be unloaded and collected in suitable bins. Due to action of an exchange valve, oleodynamic piston, arrived at the end of its run, reverts the run and steps back, so to keep free the compression chamber that in this way can receive other material to compact. Water of initial drainage and the one coming from compaction of material, are collected in a tank located below compactor and are evacuated by discharge. Tank is equipped with washing rack for cleaning.

Degritting Degreasing

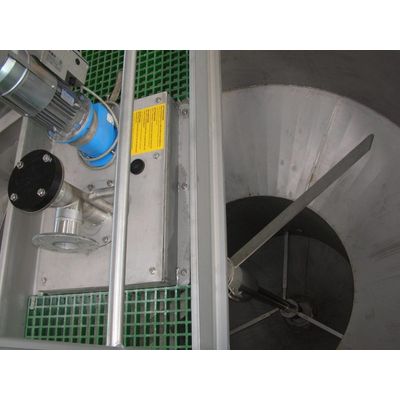

Cosmetics - Sand Trap

Sand trap pista type is used in small-medium plants to separate water from sand. Water to treat is feeded, through a tangential channel, inside tank with circular shape, having bottom with conical shape. Mixture of water and sand is kept in continuous rotation by the force of water itself and by continuous rotation of special blades installed on machine. The particular motion, due to mechanical action of blades, creates secondary transversal currents that, overlapping to the main current of sewage, help concentration and selection of sand in the bottom conical part of tank. Sand settled in the bottom, is sucked by Airlift, while instead the clarifier water exits from the discharge channel.

Biological Treatment and Aeration

Poliatex - Air Diffuser

Air diffuser made in poliatex sponge, is used in the purification plants, to oxygenate and aerate sewage to treat. Diffusers are installed on bottom of tanks and are connected to an air distribution network, feeded by blowers. Air injected on diffusers passes through the sponge material, creating medium-small bubbles (from 2 to 6 mm). The continuous exchange of oxygen, keeps sewage mixed.

Mechanical Treatments

Cosmec - Scraping Bridge with Peripheral Traction

The bridge is placed on a settling tank, at ascensional flow, with cylindrical form and base like an overturned cone. The mix of water and sludge enter in a proper central diffuser cylinder. The sedimentable solids, due the gravity, use to settle on the bottom from where, by suitable scrapers, placed on a girder anchored to the centre of the sedimentation tank and with peripheral traction, are sent to the central part of the cone and extracted by pump. The clean water flows out by a proper profile placed around the peripheral side of the sedimentation tank. The floating substances, are stopped by a suitable board, placed inside the profile where the water flows out, and conveyed by the surface blade to the collecting and expulsion box.

Sludge Treatment

Cosme - Dynamic Thickner with Rotating Drum

Dynamic thickner type CAD is a rotating drum machine, which is able to thicken the sludges not thickened, till arriving to a concentration of 10-12%. The flocculated sludge is conveyed inside the thickening drum. Flocculated sludge is drained by the belt in polyester, which wraps completely the drum. Water present in the sludge passes through the belt and is collected by the bottom tank, then it is discharged. Sludge remained on the belt is conveyed towards the external side of drum by the internal screw. Screw does also function of mechanic retention, in the sense that it increases times of staying of sludge on belt. Drained and thickned sludge is unloaded outside by the exit opening and is discharged in a collection tank, or in one of our belt filter presses, to be pressed more and dehydrated.

Tertiary Treatment

Cosme - Drum Micro Filtration System

Water containing the solid particles in suspension enters into the filtering drum and, due to hydrostatic pressure, passes through the membranes depositing on them the impurities. In this way, holes of membrane clogg, and increases resistance to passage of liquid. Also, upstream level of water rises till the intervention of system which controls rotation of drum, to provide cleaned filtering belts at passage of water. In the same moment, starts the system for counter-washing of the clogged belts, restoring the original properties of machine.

Completion Equipment

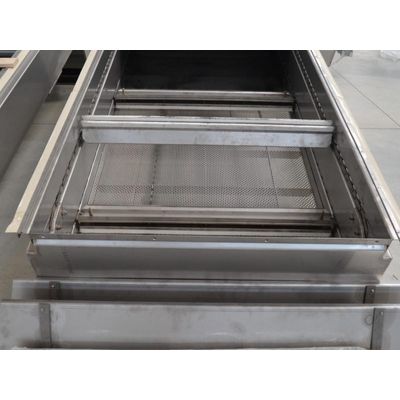

Cosme - Belt Conveyors

Belt conveyor is used to transport discharged material from a screening station to a point of collection. Movement of belt is made by rollers and gearmotor. Material to transpor remains in the middle of belt, due to presence of lateral sides. Scraper, located in the zone of discharge, grants the continuous cleaning of belt. Belt conveyors can work with inclination from 0° to 30°.