Fine Fiber Technology provides the highest filtration efficiency and longest filter life. Filtrations efficiency is exceptional at 99.99% on 0.5 micron dust particles. Easy filter change out for quicker maintenance. Continuous-duty, pulse-cleaning design for continuous operations. Lower operating pressure drop reduces operating costs. Optional Combination Starter Fused Disconnect Motor Starter.

- Home

- Companies

- Crystal Mark, Inc.

- Products

Crystal Mark, Inc. products

Standalone Units to Fully Automated Systems

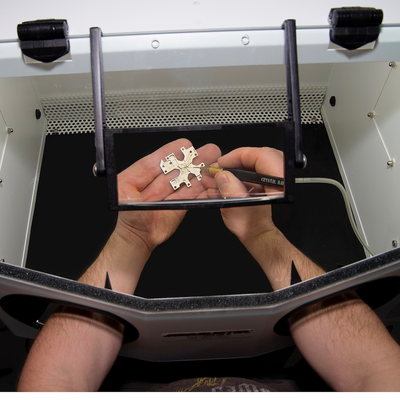

Crystal Mark - Work Center

The NEW Work Center is a modular design. Call Crystal Mark, Inc. their staff will help you to configure this NEW Work Center to meet your needs.

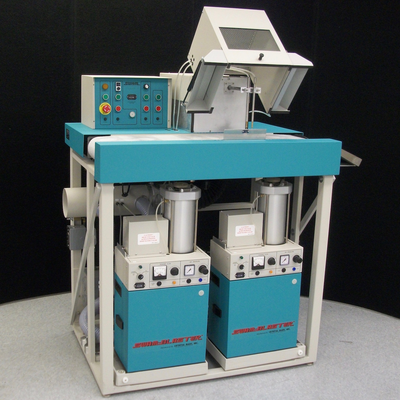

Crystal Mark - Model SWAM - Belt Abrading System

The SWAM® Belt Abrading System precisely abrades uniform finishes to surfaces requiring exact repeatability. The process begins when substrates are loaded manually or automatically onto a conveyor belt. The belt then transports the substrates into the abrading area where one nozzle or up to as many as eight nozzles reciprocate up to 14” uniformly over the moving substrates. The substrates are fully supported by the perforated conveyor belt and held in place by the vacuum of the dust collector.

Crystal - Model SWAM - Rotary Work Cell – Single Spindle Abrader

The SWAM Rotary Work Cell is built upon the Complete Work Cell concept requiring a single power and single air drop. It is compact & mounted on castors for easy installation and work cell re-configuration. When consistency is demanded this Abrading System is ideal for texturing or de-burring a variety of components including dental implants and surgical bone screws. When long parts require complete coverage, a linear motion option can support one or more nozzles. Chucks can be designed to mask areas, such as the base of dental implants, that must not be sandblasted. The Rotary Work Cell automated system is custom built from standard components for your application.

Crystal Mark - Model SWAM - Dual Spindle Rotary Abrading System

The SWAM Dual Spindle Rotary Abrading System is designed for maximum throughput. When consistency and production is demanded, this Abrading System is ideal for texturing or de-burring a variety of components including dental implants and surgical bone screws. The rotary table allows the operator to load/unload a part while a part is being sandblasted.

Swam Blasters: Heart of Crystal Mark Technology

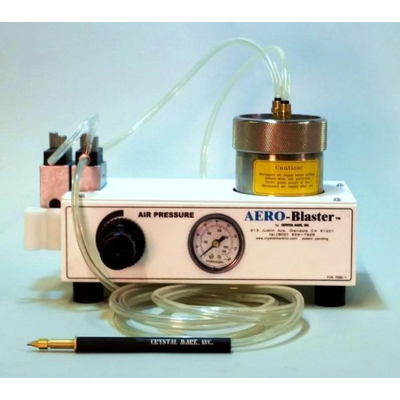

Crystal Mark - Model AERO-Blaster - Micro Sandblasters

The AERO-Blaster is designed to propel a finely graded abrasive in an air stream or just a blast of air delivered to the nozzle at the touch of a button on the hand-piece assembly.

Crystal Mark - Model EV-2 - Micro Sandblasters

The Model EV-2, Micro Swam Blaster is designed with independently adjustable powder flow control, air pressure regulation for total process control, and brass fittings throughout the abrasive pathway.

Crystal Mark - Model EV-2L - Micro Sandblasters

The Model EV-2L, Micro Swam Blaster is designed with independently adjustable powder flow control, air pressure regulation for total process control, and brass fittings throughout the abrasive pathway.

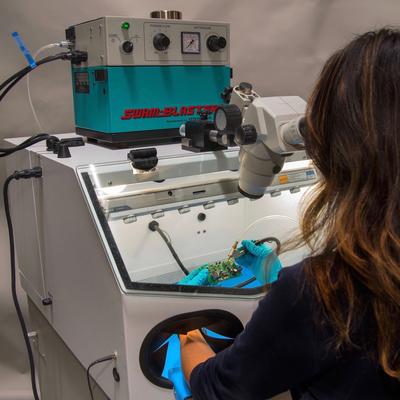

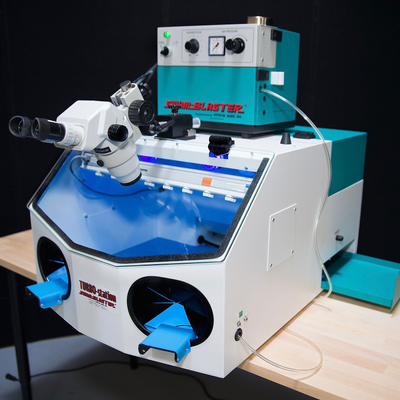

Work Chambers

Crystal Mark - Model TURBO-Max - Bench Top Work Chambers with Built-In Dust Collection

Work chamber contains the spent abrasive powder, makes the object to be processed clearly visible, and protects the operator. Crystal Mark offers work chambers with different sizes, each with required air flow and built-in dust collector. The TURBO-Max and TURBO-Station™ utilize the same filter and fan. TURBO-Max™ Approximate Size: 27”W x 35”D x 19”H. TURBO-Station™Approximate Size: 20”W x 24”D x 16”H.

Dust Collectors

Crystal Mark - Model 64 & 75 - Dust Collector

The Model 64 and Model 75 Dust Collectors provide high efficiency air cleaning. With the fan on the clean air side, dust and other collected material are filtered out by the fabric filter before reaching the fan, resulting in long, reliable performance.