- Home

- Companies

- Crystal Mark, Inc.

- Products

- Crystal Mark - Model SWAM - Belt ...

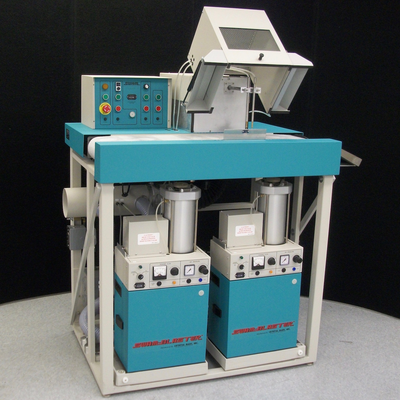

Crystal Mark - Model SWAM -Belt Abrading System

The SWAM® Belt Abrading System precisely abrades uniform finishes to surfaces requiring exact repeatability. The process begins when substrates are loaded manually or automatically onto a conveyor belt. The belt then transports the substrates into the abrading area where one nozzle or up to as many as eight nozzles reciprocate up to 14” uniformly over the moving substrates. The substrates are fully supported by the perforated conveyor belt and held in place by the vacuum of the dust collector.

Crystal Mark has developed conveyorized abrading systems using belts that are 5”, 7”, 9”, or 16” wide.

The design can be adapted as required to integrate with the production environment.

Applications include surface texturing, selective etching, surface finishing or plating preparation of quartz, glass, ceramic, plastic, metals and many other materials requiring a uniform surface.

- The Model C129 Belt Abrader features two Model LV-1 or Model XV-1.

- The Model C149 Belt Abrader features four Model LV-1 or Model XV-1.

- The Model C169 Belt Abrader features six Model LV-1 or Model XV-1.