DeepOcean services

Survey & Seabed Mapping

Seabed Mapping Service

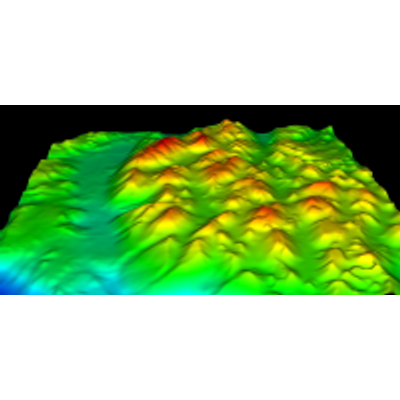

Towed Side Scan Sonar or Multibeam are predominantly used to obtain the data required to produce high quality Digital Terrain Models (DTM`s). This type of survey would be undertaken as part of a Route Survey which is necessary for the planning of pipeline installations. This type of survey enables the topography of the seafloor to be examined for wrecks, manmade artifacts, debris and other points of interest. This ensures that pipes and cables are not laid in potentially hazardous areas. The composition of the seabed can also be determined for burial and trenching evaluation.

Route Survey Service

DeepOcean will plan and deliver route surveys and seabed mapping for subsea module/rig, cable, pipeline and flexible installation and trenching projects. Using the latest survey techniques and ROV and vessel mounted equipment, the route is verified as being safe, clear of obstructions and as planned in order to ensure the work can take place without incident or interruption. DeepOcean will advise on obstructions and the potential solutions to enable the project to proceed. This advice can include understanding the limitations of the constructions, installation and trenching activities and the associated risks. This service can be provided as a standalone service but is often integrated in to the installation, construction or trenching contract and vessel.

Pipeline Survey Service

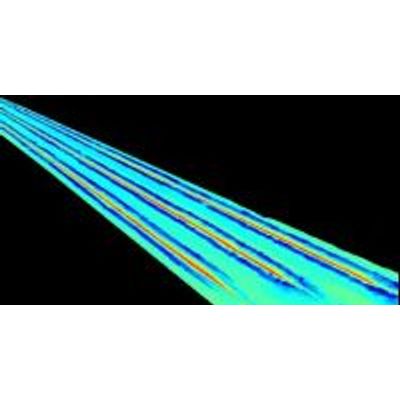

Seabed and product profiling is carried out using Dual Head Multibeam Echosounder systems. DeepOcean is a major supplier of pipeline inspection surveys for detecting free-spans, damage and defects, leaks, cathodic erosion and pipeline movement. Our survey and inspection vessels are equipped with ROVs fitted with video cameras, acoustic scanning systems, CP probes and pipe-trackers to locate buried lines and with ROTs for acoustic pipeline surveys.

Seabed Intervention

Mechanical Cutting Service

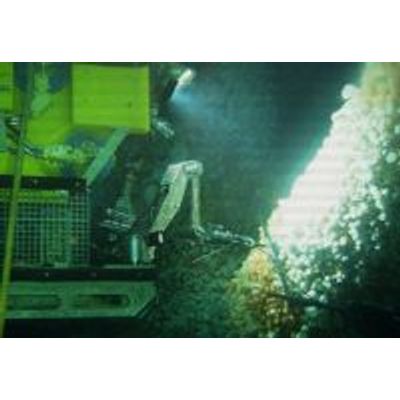

DeepOcean owns and operates mechanical trenchers ranging from T-3200, the most powerful underwater tracked vehicle in the world, to the smaller, lighter vehicles, T1 and T2, through to the Shallow Water Trencher, SWT-1. These trenchers can operate in either jetting or cutting modes, depending on the project requirements. DeepOcean has developed a proven track record for the burial of pipelines, flowlines, umbilicals and submarine cables, including Life of Field Seismic (LoFS) systems and power cables.

Inspection, Maintenance And Repair (IMR)

Structure Inspection Service

Structural inspection is performed on subsea structures, offloading systems, risers and umbilicals, steel jacket platforms, floating platforms and FPSOs by personnel specially trained for this type of work. The intention is typically to evaluate the condition of the structure and check for leaks, cracks, defects and damages. DeepOcean have extensive experience in performing structural inspections in harsh weather conditions and thus extending beyond the traditional seasonal windows of operations.

Construction Operations Service

DeepOcean perform a range of construction related work in addition to typical IMR tasks. This is achieved by flexible designed DP vessels with typical more than 100 Te Active Heave Compensated crane, 2 or 3 ROVs, and large deck space suitable for mobilising the required equipment and products for the job.

Decommissioning

Disposal Service

DeepOcean provide project management, operational planning, engineering, mobilisation/ demobilisation, ROV vessel, offshore crew and have the overall responsibility of disposal as part of a decommissioning program. Many old jacket type platforms will have to be removed more or less completely in the years to come – dependant on the regional and national requirements for the production block. Concrete gravity based platforms may be left upon closure of production, however typically steel and parts subsea in excess of one meter from the concrete must be removed. All parts must be brought ashore for considerate disposal.