- Home

- Companies

- DEL Corporation

- Products

DEL Corporation products

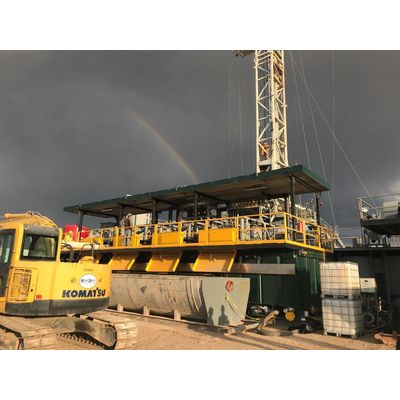

DEL KODIAK - Total Clean Mud System

The KODIAK TOTAL CLEAN Mud System (U.S. PATENT 10,857,488) takes mud cleaning and solids control to another level with its unique design and process flow. Rig shakers, settling pits, and drying shakers are obsolete and unnecessary. The KODIAK takes the mud directly from the rig flowline, cleans the mud and dries the cuttings. The clean mud from the Kodiak then equalizes with the rig intermediate tank. The KODIAK is the system mud companies, waste disposal companies, diesel suppliers, and screen suppliers hate. Watch the video above and then call a DEL sales representative to learn how it works.

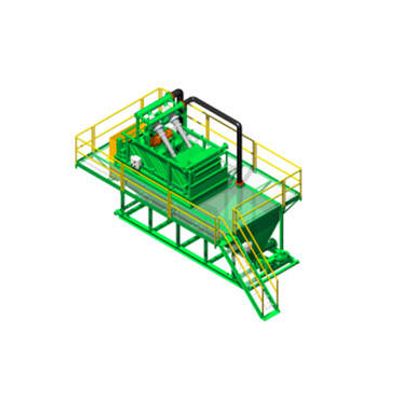

DEL SANDCAT - Total Clean Flowback System

The SANDCAT Total Clean Flowback System's innovative design and cutting-edge technology provides efficient, cost-savings solutions for completion operations. Cleaner fluid, drier sand discharge, and seamless operation makes the sandcat the premier flowback system.

DEL - Mix Tanks

DEL, always striving to meet the needs of its customers, has been instrumental in the development of mobile mix tanks, as well as skid mounted for fixed location operations. DEL provides mix tanks in sizes up to 45,000 gallons. DEL`s Bullet Style tanks are designed to save customers money on labor and help eliminate downtime. With (4) 10hp mixers, round bottom and smooth walls, the Bullet Mix Tank promotes uniform solid suspension and mixing that virtually eliminates build up which can lead to downtime and additional tank cleaning costs. The easy access hatches and clean-outs, as well as the round bottom makes the decontamination process fast and easy, therefore reducing unprofitable labor hours.

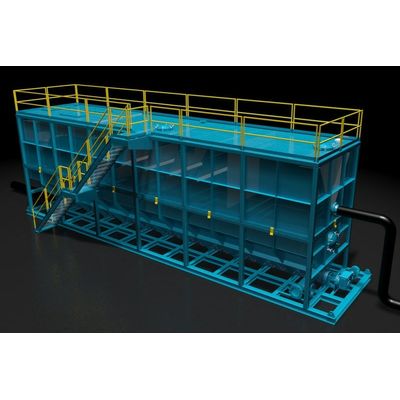

DEL - Mobile Clarifiers & Thickeners

DEL has designed a versatile and mobile Clarifier & Thickener to handle the higher flow rates required by many dredging and dewatering projects with a total working capacity of 45,000 gallons. The tank is built in 2 sections, an upper and lower section, for ease of transport. The tank requires only 2 flat bed trucks and width permits for hauling. The flange joining the 2 sections together is designed for fast, leak free assembly. The tank can be unloaded and assembled on the job site and ready for use in a matter of a few hours. The tank is equipped with a tilted plate baffle system, settled solids conveyance system and effluent overflow trough system to provide removal of settled solids and discharge of a clean effluent. In most cases flow rates up to 3,000 gpm can be accommodated.

Scalping Classifying Tank

DEL Scalping Tanks are designed to handle flow rates up to 10,000 gpm. The V-Bottom tank, along with the shaftless auger, will eliminate unwanted downtime for cleaning out the tank when solids have settled out. These systems are available with and without mixers and are offered in many different configurations in order to meet the customer’s requirements.

Frac Tanks

DEL offers a wide variety of FRAC Tank sizes with several options to choose from.

Total Clean Systems

DEL - Model 350 - Dredge Dewatering Total Clean System

DEL’S patented Total Clean System is the most valuable component of any dredge dewatering project besides the dredge itself. On most dredging projects the Total Clean System will remove and dewater 60% or more of the dredged material and at a cost much less than any other dewatering method. The Total Clean will receive the initial flow directly from the dredge and remove all the oversize debris, usually +1/8”. The remaining slurry is then pumped to the hydrocyclone/shaker units where typically the sand fraction, +74 microns is removed. Any solids remaining in the hydrocyclone overflow and screen underflow then flows through the tilted plate baffle section of the V-Tank.

DEL - Model 750 - Compact Dewatering System

DEL’S patented Total Clean System is the most valuable component of any dredge dewatering project besides the dredge itself. On most dredging projects the Total Clean System will remove and dewater 60% or more of the dredged material and at a cost much less than any other dewatering method. Realizing the need for a smaller, more compact dewatering system, DEL developed the Total Clean 750 for flow rates up to 750 GPM. With its small footprint, the 750 is ideal for smaller projects where space is limited.

DEL - Model 1500 - Dredge Dewatering System

DEL’S patented Total Clean System is the most valuable component of any dredge dewatering project besides the dredge itself. On most dredging projects the Total Clean System will remove and dewater 60% or more of the dredged material and at a cost much less than any other dewatering method. The Total Clean will receive the initial flow directly from the dredge and remove all the oversize debris, usually +1/8”. The remaining slurry is then pumped to the hydrocyclone/shaker units where typically the sand fraction, +74 microns is removed. Any solids remaining in the hydrocyclone overflow and screen underflow then flows through the tilted plate baffle section of the V-Tank.

DEL - Model TCW-3000 - Total Clean System

DEL’S patented Total Clean System is the most valuable component of any dredge dewatering project besides the dredge itself. On most dredging projects the Total Clean System will remove and dewater 60% or more of the dredged material and at a cost much less than any other dewatering method. The Total Clean will receive the initial flow directly from the dredge and remove all the oversize debris, usually +1/8”. The remaining slurry is then pumped to the hydrocyclone/shaker units where typically the sand fraction, +74 microns is removed. Any solids remaining in the hydrocyclone overflow and screen underflow then flows through the tilted plate baffle section of the V-Tank.