Dinex A/S products

Pipe Treatment Systems

Dinex - Exhaust Pipes

At Dinex, we consider the exhaust system as a high technology system, which provide a safe exhaust path between the turbo and the after-treatment system. The ATS system requires high temperatures in order to provide the right emission levels according to the standards that have pushed the demand for higher technology solutions.

Spark Arrestor

Catalysts

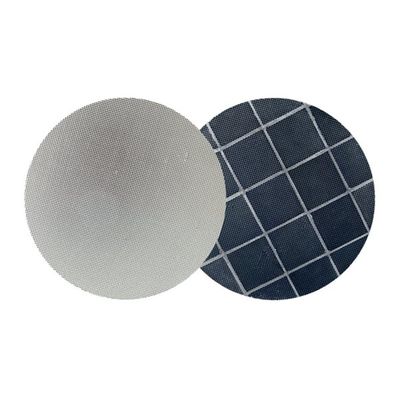

Our world class catalyst products are the result of in-house developed formulations and metallic substrates. A powerful combination of high-performing coatings and durable substrates that translates into innovative products designed to tackle the most stringent emission requirements. Through our versatile approach and customization abilities, our customers are always able to find a solution for their emission control needs.

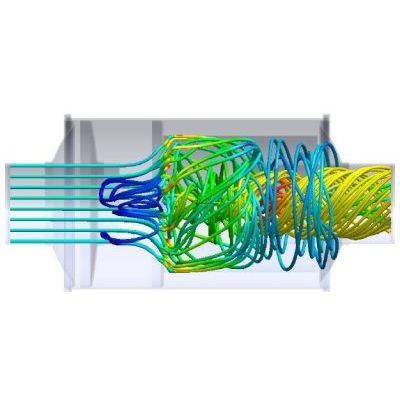

Mixers

The main purpose is to enhance the evaporation and thermolysis of the injected urea water solution (UWS) while limiting wall film and deposits. Thin sheet metal is bended and clinched together inside a small pipe with welding exterior to where urea is present to avoid deposit build up.

Catalyst Coating Technologies

Dinex - Model DOC - Diesel Oxidation Catalyst

The primary function of DOC in a Diesel ATS is to ensure sufficient oxidation of CO and THC, and to oxidise, NO in the exhaust to NO2.

Dinex - Diesel Particulate Filter Coating (C-DPF)

The primary function of DPF in a Diesel ATS is to trap and oxidise the soot particulates in the exhaust. The DPFs are typically coated with a low PGM content wash coat and are typically known as catalysed DPFs (C-DPF) to ensure further oxidation of NO towards NO2 within DPF and to assist in keeping the soot amount in DPF below the designated level. Dinex DPF coating technologies are based on a high thermal stability wash coat formulation with excellent NO2 recycling / formation characteristics. The PGM loading can be modulated based on the application and the typical duty cycle requirements.

Dinex - Selective Catalytic Reduction (SCR)

The primary function of SCR catalyst in a diesel ATS is to convert harmful nitrogen oxides (NOx = NO + NO2) in the exhaust gas to nitrogen and water. The SCR reaction takes place on the catalyst, in the presence of NH3 generated from AdBlue (Urea and water solution) upfront the SCR catalyst. Advanced emissions regulations like EU VI /EPA/China N6/Bharat 6 need above 95% NOx conversion levels and all Dinex SCR technologies achieve conversion levels well above this limit.

Dinex - Model SCR-DPF - Coating Technologies

SCR-DPF technology integrates the SCR reaction function into the particle filter (DPF) by enabling compact ATS systems, quick warm up and early dosing possibility. This relatively new technology has quickly gained relevance and application in off-road segment, where especially space restriction is a key challenge. Dinex SCR-DPF coating technologies are zeolite-based and offer excellent NOx conversion levels while also typically offering a 20% reduction in overall ATS volume.

Dinex - Model TWC - Three-Way Catalyst

The primary function of a three-way catalyst (TWC) in a CNG/LNG ATS is to convert and minimise emissions of harmful species like THC, CO and NOx below the regulatory limits. The TWC by Dinex is a Pd-Rh-based technology with high surface area wash coat formulation which contains high oxygen storage capacity (OSC) materials, stabilisers and promoters with optimised active (PGM) metal content.

Dinex - Model MOC - Methane Oxidation Catalyst

The Dinex methane oxidation catalyst for lean-burn CNG engines is based on a high surface area wash coat with Sulphur resistant components. It is suitable for mobile or stationary applications. The highly dispersed PGM nanoparticles with Pt-Pd or Pt only formulation suit the emission demands according to the requirements. It is available on metallic as well as on ceramic substrates with excellent adhesion.