- Home

- Companies

- Dynaflow, Inc.

- Services

Dynaflow, Inc. services

Consulting And R&D

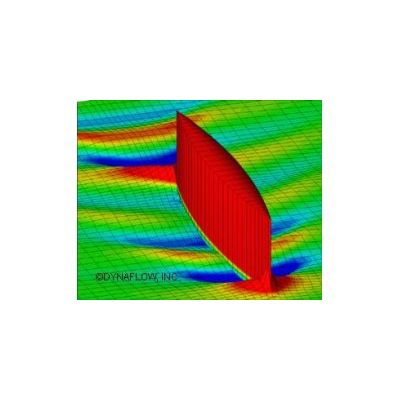

Modeling & Simulation

Dynaflow, Inc. is actively engaged in the development and utilization models and simulations of a range of fluid dynamic phenomena. Dynaflow seeks to develop and utilize the best tool for a given problem. The strength of our modeling and simulation efforts is that they are based on the underlying physics of the pehnomena.

Inverse problems

Inverse problems are problems where the solutions are nearly always indirectly related to the available data and where causes are determined for desired or observed effects. The problems are often ill-posed in that small changes in the data can produce large effects in the solution. Furthermore, questions of whether a solution that corresponds to likely noisy data can exist and how many and how different solutions there may be that correspond to partial data sets need to be considered. To overcome these difficulties, special mathematical treatments need to be utilized. Dynaflow has developed proprietary numerical algorithms and software that implement these treatments to enable obtaining a stable and physically accurate solution for a number of applications.

Flow Visualizations

Understanding moderate to high speed phenomena such as explosion and cavitation bubble dynamics, liquid drop impact, and vortex and jet flows is facilitated with still, video, and high speed movie photography.

Material Erosion Testing

Dynaflow, Inc. has experience with numerous research projects on materials resistance to erosion by cavitation and liquid droplet impact. We offer our experience and testing capabilities to our customers.

Bubble Dynamics / UNDEX

Dynaflow, Inc. conducts a full range of research, development, and consulting studies on bubble dynamics including analytical, numerical and experimental work. Often a combination of these techniques is used to solve a given problem. A wide range of numerical methods, including one-way and two-way bubble/flow interaction schemes, spherical and non-spherical bubble deformation models, boundary and vortex element methods, and Navier-Stokes simulations have been developed to study bubble dynamics in a broad range of flow conditions. Our experimental facilities including high speed photography are used in conjunction with the numerical models to study bubble dynamics as well as to validate the numerical simulations.

Hydrodynamics

Dynaflow, Inc. is involved in theoretical, numerical, and experimental studies of fundamental fluid mechanics and naval, environmental, medical, and industrial applications. Through years of theoretical and experimental investigations of free surface problems including bubble dynamics, cavitation, and surface waves, we have developed proprietary numerical codes that can predict flow fields for many types of free surface related problems. We have successfully applied our capabilities to challenging hydrodynamics problems with free surface/bubble-body interactions, jets, vertical flows, extreme deformation of free surfaces, etc.

Testing

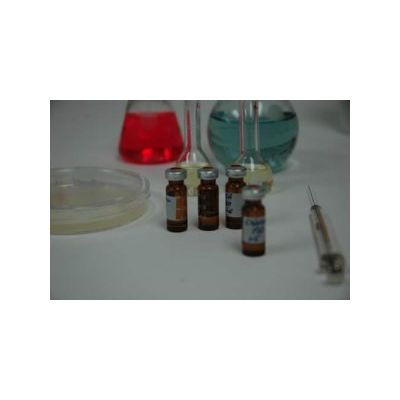

Chemical And Microbiology Laboratories On-Site Analysis Services

Dynaflow has chemical and microbiology laboratories on-site. Analytical chemistry capabilities include trace organic analysis of water and air using gas chromatography (GC/FID and GC/PID) and mass spectroscopy (GC/MS with EI/CI/NCI). Several water quality analyses are also available including, pH, Total Organic Carbon (TOC), Chemical Oxygen Demand (COD), Biochemical Oxygen Demand (BOD), Total Phosphorus, Nitrate and Nitrite, Iron, Total Solids (TS), Total Suspended Solids (TSS), and Volatile Suspended Solids (VSS).

Environmental Chemistry & Engineering Services

Dynaflow can develop gas chromatography (GC) and mass spectral (GC/MS) analytical methods including extraction methods, matrix effects, GC methods, MS detection methods, and Method Detection Limit studies.