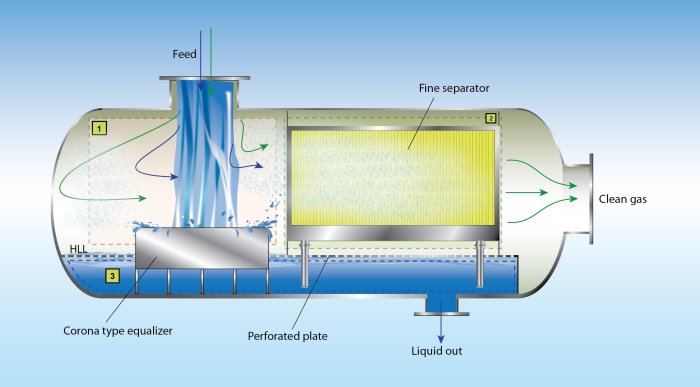

ENSEPATEC - Horizontal Knock-out Drum

The horizontal knock-out drum targets at applications with high liquid loads and fine removal efficiencies between 5 and 20µm. The length is dictated by the internal diameter (ID), the gas volume flow and the required efficiency. The horizontal KO-drum accommodates internals such as inlet gas distributors, perforated plates, vane type separators and coalescing pads. The separator is split into 3 zones of different functions.

Zone 1 is the inlet liquid KO- and gas-distribution zone. The incoming liquids slugs are knocked-out inside a corona equalizer, when coming from a top feed-nozzle.

Zone 2 is the fine separation zone that accomodates the separation internals - dual or single pocket vane type separators with and without perforated plates and coalescing pads.

Zone 3 is the liquid collection and drain zone. Its height varies with the high liquid level requirements and other process related parameters.

The liquid removal capacity of the horizontal KO-drum depends mainly on the internals diameter and the L/G ratio (liquid to gas ratio). L/G ratios can be easily >30.

The particle size removal efficiency for small droplets typically ranges between 5 and 20µm when used with a coalescer pad.

The pressure loss varies with the choice of internals and can be adjusted according to the operation requirements.