- Shredding Machines

- Shredding Machines - Cardboard Shredder

- Shredding Machines - Hammermills

- Shredding Machines - Used Machines

- Shredding Machines - Used Machines - Single-Shaft Shredder (Used)

- Shredding Machines - Used Machines - Three-Shaft Shredder (Used)

- Shredding Machines - Used Machines - Swarf-Shredding-Drum (Used)

- Used Machines

- Others

Erdwich Zerkleinerungs-Systeme GmbH products

Shredding Machines

Erdwich - Single-Shaft Shredder

Achieving precision material breakdown in just a single operation: that’s the proven capability of the Erdwich single-shaft shredder.

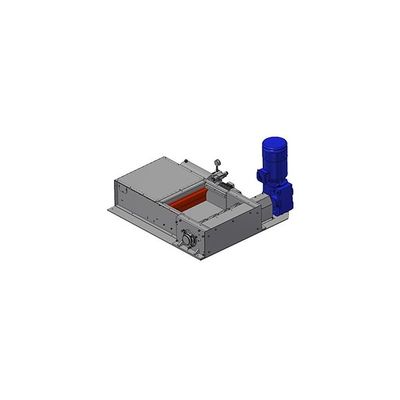

Erdwich - Two-Shaft Shredder

Continuous-process shredding of large quantities and volumes: that’s the world of the ERDWICH two-shaft shredder. The secret of its success is our ERDWICH rotor-blade cutting principle, honed to perfection over decades. Want to know more?. The material is taken up by the barbed blade, pulled unceremoniously into the machine and then shredded between the blades on the two opposing shafts. Whatever the material – e.g. special waste, WEEE, metal swarf, electrical waste or bulky items – even hard to shred, large-volume materials stand no chance against these two mighty cutter shafts. Perfect results are even guaranteed from fibrous, moist, heat-sensitive, elastic and rubbery materials. And, thanks to its mode of operation as a slow-speed piece of equipment, the ERDWICH two-shaft shredder also features quiet and largely dust-free operation. You can rely on the power and the technology of the ERDWICH two-shaft shredder.

Erdwich - Three-Shaft Shredder

The uniform shredding of coarse materials: that’s the speciality of the ERDWICH three-shaft shredder. ERDWICH has created the three-shaft design especially for these requirements. Entirely free of clogging and jamming – even with solid materials. Clever, huh?. Absolutely: after all, the three cutter shafts and their individual sets of blades rotate at different speeds, so as to continuously pull in and precisely shred the feedstock material. If the material is too large, the sweeper shaft simply transfers the material to the lower cutter shafts for further size reduction. Again and again – until the material is the exact size as specified. Tirelessly, and with perfect reliability. Fragment size selection itself is achieved by the perforated screen substructure through which the material exits after the shredding process.

Erdwich - Model RM 1350/2 and RM 1800/2 - Two Shaft Ripper

The specialist for coarse materials. When processing coarse materials such as electronic scrap, refrigerating devices or die-cast aluminium parts, it is important to keep the individual components as intact as possible and to process them gently, in addition to maximum process reliability and performance. This is where our RM 1350/2 and RM 1800/2 twin-shaft rippers prove what they are capable of: The particularly slow-running twin-shaft rotor ripper system is used to work especially gently. Two machine sizes with different ripper lengths and drive powers are available for every challenge.

Shredding Machines - Cardboard Shredder

Erdwich - Model EKZ Series - Cardboard Shredder

Economical solutions for the shredding and preparation of cardboard. The reduction of transport costs, the reduction of material for feeding to existing press containers or balers as well as the shredding of material for conveyor belt feeding are good reasons for the use of cardboard shredders. With the EKZ cardboard shredder and FKZ fine cardboard shredder, we have two robust and absolutely reliable machines in several sizes in our product portfolio. Whether it is the shredding of packaging or the preparation of cardboard waste for suction into existing conveying systems, we always offer you a perfect solution tailored to your needs.

Erdwich - Model FKZ Series - Cardboard Shredder

FKZ - Fine cardboard shredding for volume reduction. In addition to our proven EKZ, another machine has been developed to shred cardboard waste to a piece size. This enables pneumatic disposal directly at the material accumulation point. The FKZ fine shredder is ideally suited for processing punching remnants or individual sheets from cardboard production. By using the ERDWICH FKZ fine cardboard shredder on your production machine, in-house disposal of filled waste containers is no longer necessary. This saves time and costs and also ensures a smooth process flow for you.

Shredding Machines - Hammermills

Erdwich - Model HA600 - Hammer Mill

The champions for hard and brittle materials. Hammer mills are particularly suitable for metal scrap, electrical and electronic scrap or chips made of steel, aluminum, but also other materials. And due to the easy adjustability during operation, also the balling of non-ferrous metals is no problem. The result size is variable and can be changed during operation. This product feature in particular is the best example of its high practical suitability.

Erdwich - Model HA800 - Hammer Mill

The champions for hard and brittle materials. Hammer mills are particularly suitable for metal scrap, electrical and electronic scrap or chips made of steel, aluminum, but also other materials. And due to the easy adjustability during operation, also the balling of non-ferrous metals is no problem. The result size is variable and can be changed during operation. This product feature in particular is the best example of its high practical suitability.

Shredding Machines - Used Machines

Model RUF 30/3700/100 - Briquetting System

Machine number: 2885. Year of manufacture: 02/2019. Voltage: 400 V. Rated current: 68 A. Cycle: 50 Hz. Hydraulic oil: HLP 46 – 500 ltr.

Shredding Machines - Used Machines - Single-Shaft Shredder (Used)

Erdwich - Model M500/1-600-5,5 kW - Single-Shaft-Shredder

Machine number: 1618. Cutting size: 600 x 580 mm. Drive power: 5,5 kW. Blade width: 25 mm. Number of blades: 25 pieces. Blade shape: 3-hooked. Perforation diameter: 8 mm. Construction year: 2006. Cutting unit without funnel, frame and control.